DAYO is a company specialized in industrial assembly and maintenance. Our day to day is between production processes, so we offer our clients a complete lockout / tagout program, to reduce risks and improve safety and health at work.

Innovation

At DAYO we continually improve. We have customers from every industry and we strive to stay ahead of their needs by continually investing in research to deliver even higher performing solutions. By developing more efficient and user-friendly concepts, we offer the best in the market to our customers.

Advantage

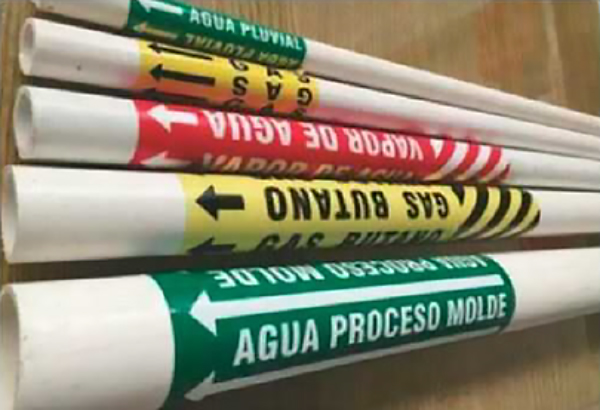

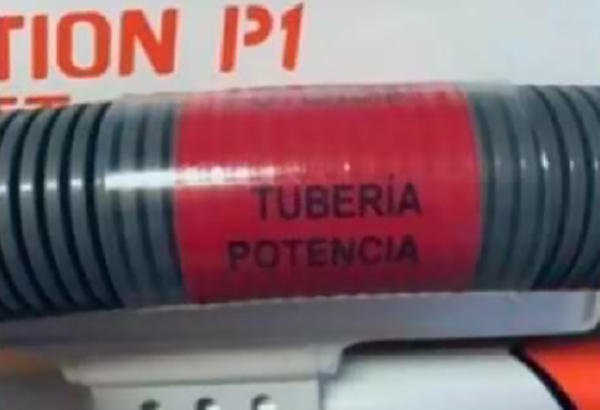

At DAYO we believe that one of our greatest advantages is the wide range of identification and security solutions that we offer to our customers, be it the labeling of smaller components or the complete marking of an entire warehouse. We also pride ourselves on offering many products and services – from printers, scanners and software to on-site training and service contracts, complementing any identification work.

Confidence

DAYO has been linked to quality, trust and stability for many years.

We demand the best from our products and services because we know better than anyone the importance of good and reliable identification. Identification seems like an additional detail, but all professionals know that this type of detail is crucial for any business.

Why and how it is implemented a blocking program / labelled

Use this reference guide to better understand lockout / tagout procedures. In the catalog you can find more detailed information about locking devices and labels.

- What is a lock / tag and why work with it?

- Why implement a lockout / tagout program?

- Effective locking program in 4 steps

- Compliance with legal requirements

- ATEX certification

- Security software and services

- Effective control of hazardous energy

Labeling SAVES LIVES!

What is lockout / tagout?

Lockout / Tagout is a planned safety procedure that involves disconnecting the power source of industrial machinery and equipment while any maintenance or repair work is being performed. This procedure protects workers against the hazards posed by electricity or active machinery.

Implement a lockout / tagout program?

Lockout / Tagout is a planned safety procedure that involves disconnecting the power source of industrial machinery and equipment while any maintenance or repair work is being performed. This procedure protects workers against the hazards posed by electricity or active machinery.

Lower accident rate and lower injury costs

The EU figures show that 10-15% of all fatal accidents in the workplace, and 15-20% of all accidents are maintenance-related. Among the most common injuries are fractures, lacerations, amputations, burns, and electric shocks. Due to the severity of numerous LOTO-related accidents, the costs associated with these injuries can be exorbitant.

Less downtime, higher productivity

A well-organized LOTO program that includes clearly labeled power sources, easy-to-follow procedures, and instantly accessible locking tools can significantly speed up maintenance and service activities. Workers can avoid time-consuming but essential pipe and circuit detection tasks to verify proper power control points. As a result, maintenance work is carried out more efficiently, downtime is less, and machinery operates at peak performance levels.

Lower indirect costs

Accidents can have a significant impact on work scheduling and productivity in the affected workplace. Unexpected equipment start-up can also cause significant damage to the machinery itself, adding the expense of equipment repair or replacement to the actual total cost.

Recommended security practice

Lockout / Tagout has been globally recognized as a Recommended Security Practice in many industry sectors and is a legal requirement in the United States.