LEACHATE TREATMENT TECHNOLOGY (REVERSE OSMOSIS MEMBRANES)

Given the characteristics of a standard leachate and discharge requirements, a tertiary reverse osmosis treatment is often necessary to achieve the required limits.

DAYO proposes reverse osmosis as a single treatment, in most cases without the need for biological or physical-chemical pretreatment (only for composting plants), achieving even higher yields than the use of a combination of technologies such as (CQ + Biological + UF + OI), because, in these cases, the osmosis module installed is spiral or modified spiral, being very sensitive to biological variations, losing performance capacity very quickly. The purpose of this document is to define the facilities of the purification plants by treating the open channel reverse osmosis with the ‘DISCO-PLATO’ module.

Project criteria

We present an exhaustive study of four cases based on flows of 25, 50, 100 and 200m3 / day, starting from the standard values presented for leachate obtained with our experiments, but although it is true that each component of the leachate has its own pressure osmotic, the main one is generated by the salt content, and to simplify the following study, the electrical conductivity obtained in a standard leachate based on the minimum (4mS / cm), medium (20mS / cm) and maximum (41mS / cm).

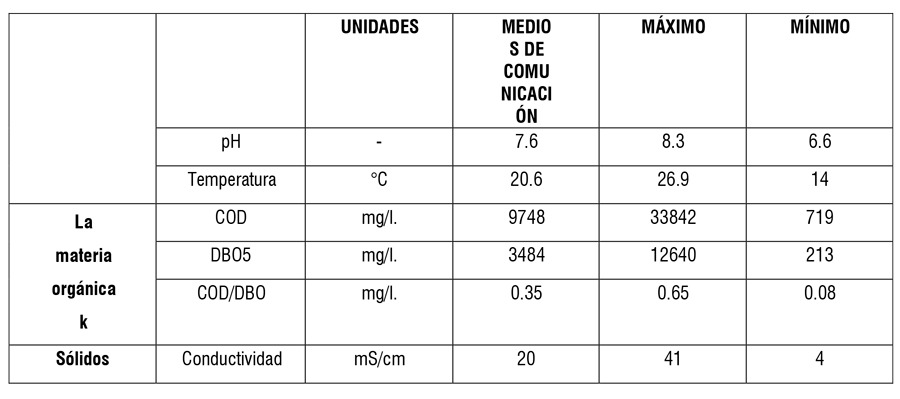

The most significant values of a leachate:

Table

In all the cases presented here, the output values are obtained on public roads.

| PARAMETERS | UNIT | VALUE |

|---|---|---|

| pH | – | 0.2 |

| DBQ | ppm O2 | 6.8 |

| BOD5 | ppm O2 | 15 |

| SST | ppm | 60.5 |

| NH4 + | ppm | 3 |

| CI- | ppm | 145 |

| Conductivity | S / cm | ~ 200 |

Description of the facility

The ‘DISCO-PLATO’ module is distinguished by its high operational availability, great flexibility in the case of variations in the flow rate to be treated, high functionality and constant quality of permeate purification. Generally, reverse osmosis occurs at values between 10 and 80 bar. In addition, DAYO offers high pressure technology that can achieve operating pressures of up to 160 bar. In these cases, to obtain maximum performance, it could work up to 80 bar of pressure using a module with a large membrane surface per module, up to 9.5 m2.

The proposed module consists of a pressure tube and hydraulic discs stacked and supported by the central axis. The octagonal membranes rest between the discs. They are formed by two polyamide membranes, welded by ultrasound, separated inside by a drainage mesh that acts as a spacer. Due to this particular design, open channels are formed between the hydraulic disc and the outer surface of the membranes, through which the feed water flows and concentrates as it moves through the stack of plates and membranes. The individual channels of each disc are linked by means of openings in the concentric discs, so that the water flows radially over the membranes, alternating from the inside to the outside and vice versa.

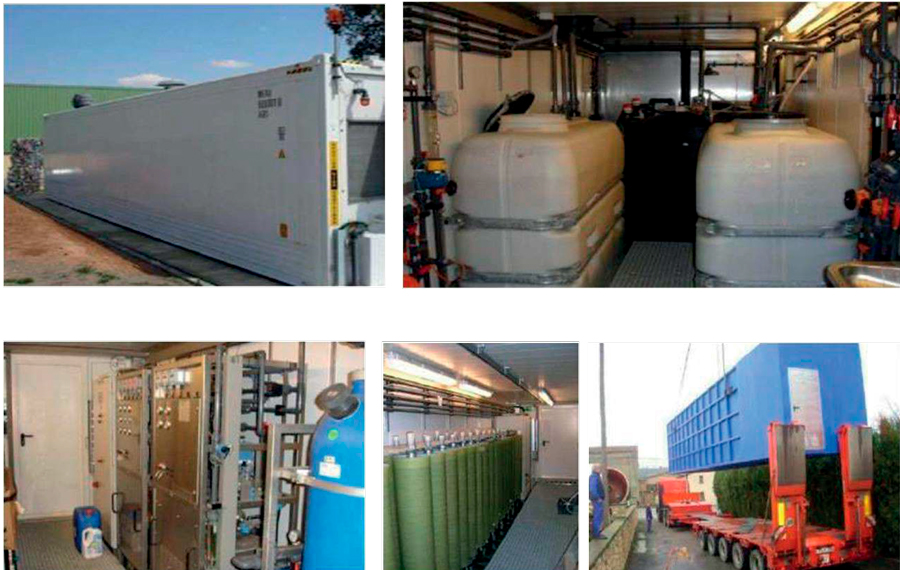

Type of installation

This type of machine can be supplied installed inside a building or in a fully air-conditioned maritime container, with quick connections for leaching hoses and outlets for purified and concentrated water and return to the lagoon, with the advantage of minimizing the works. of construction, since you only need a reinforced concrete slab.

Advantages of the system

- It is modular, compact, portable and space-like;

- High stability and flexibility to changes in the leachate;

- Reverse osmosis separation of always excellent quality;

- Variations in organic matter (BOD5, COD) do not modify the operating conditions of the plant;

- More than 90% elimination in compounds of divalent, monovalent, n-ammonia and organic ions of high weight, as can be seen in the following table:

| PARAMETERS | RO SINGLE STAGE | DUPLA RO SCENARIO |

|---|---|---|

| Monovalent ions | 96 to 98% | 99.5% |

| Bivalent ions | 98 to 99.5% | 99.9% |

| N-ammonia pH 6.5 | 95% | 99.5% |

| High weight organic compounds | 99 to 99.8% | 99.9% |

Conclusions

In summary, the treatment of leachate through a reverse osmosis process can be considered the process whose response is stable and more automated for the treatment of liquids with variable pollutant load, since it is a physical process and does not depend on the behavior of a biological mass that, once modified, requires time before recovering optimal activity.