INVERSE OSMOSIS

Reverse osmosis is based on the passage of water through a membrane, applying a pressure higher than the osmotic pressure. In this way, the water that permeates through the membrane. Reverse osmosis achieves a 99% reduction of the components present in the water, including viruses and bacteria.

Applications:

- Drinking water

- Boiler water supply

- Sea water purification

- Brackish water purification

- Ultrapure water

- Water for pharmaceutical industry

- Water reuse

DESCRIPTION / CHARACTERISTICS OF THE BIOLOGICAL PROCESS MBR

- The MBR system – bio reaction membrane – replaces the process of sedimentation, filtration, disinfection, suspension of solids by eliminating them with an ultrafiltration membrane

- The only chemical substance used in the process of conservation and cleaning of the membrane is, as a disinfectant agent, sodium hypochlorite, dissolved 20 times in a commercial 15% solution

- Ultrafiltration membranes allow to operate, with a solids level in the reactor, between 10 and 15 grams per liter

- The MBR system produces a constant effluent quality, regardless of the inflow, working with levels. Provides very effective treatment for high values, in accordance with California Title 22 regulations. The results are: BOD 5 10 mg / l, SS 5 mg / l

- It is a biological system of total oxidation with nitrification and denitrification stages

- Compared to a conventional biological system, composed of pretreatment, biological treatment, decanter, filtration and sterilization, in this system there is only one pretreatment and one biological reaction, through submerged membranes

- Allows solid / liquid separation through 0.05 micron (0.00005mm) ultrafiltration membranes

- Sanding systems and oxygen consumption are the same as conventional ones

- The membranes retain all kinds of bacteria, fungi, viruses, parasites and others, clarifying the water up to 99.99%

- There are no deposit problems in the absence of sedimentation

- The age of the sludge is much higher than that of a conventional system, which allows, as a result, that treated water of very good quality, which can be reused

- The membranes are cleaned automatically by injecting thick air bubbles into the base of the membrane, or by including a chemical for cleaning

- In suction work minimum pressures are required

ADVANTAGE

- The MBR system allows the compaction of the station up to ¼ of the area of a conventional station

- Eliminating the secondary decanter

- Wastewater treatment plants are modular, compact and portable

- Os Operating costs, including reagents and membrane depreciation, are 20% less than a conventional biological system

- Easier maintenance, because there is a reduction in the number of mechanical elements

- Excellent outlet water quality, which may be better than tertiary water

- Possibility of reuse of treated water

- Possibility of expanding existing facilities without the need for additional works

- Very good adaptation in places where there is a lot of population variability

WORKING PRINCIPLE OF THE ETAR MBR

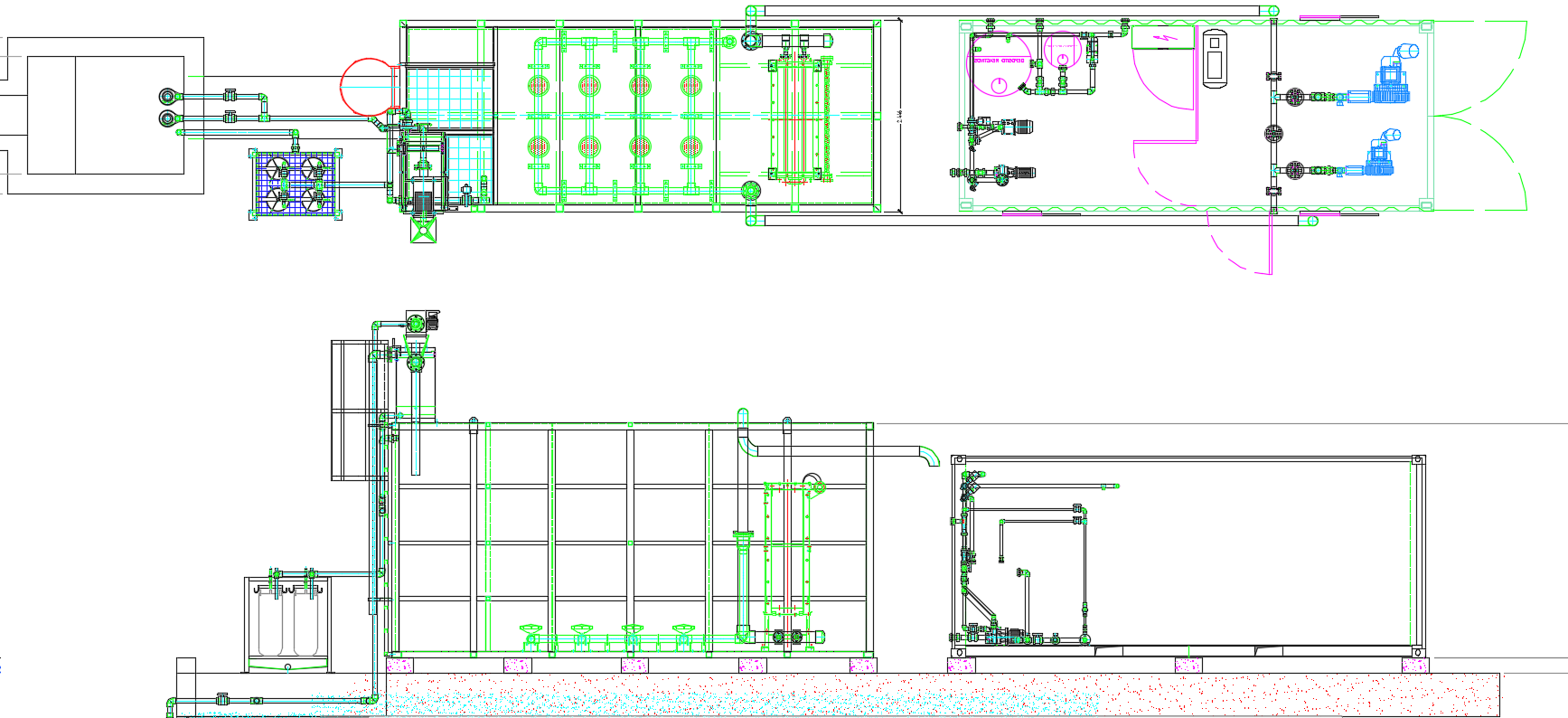

Compact plant MBR

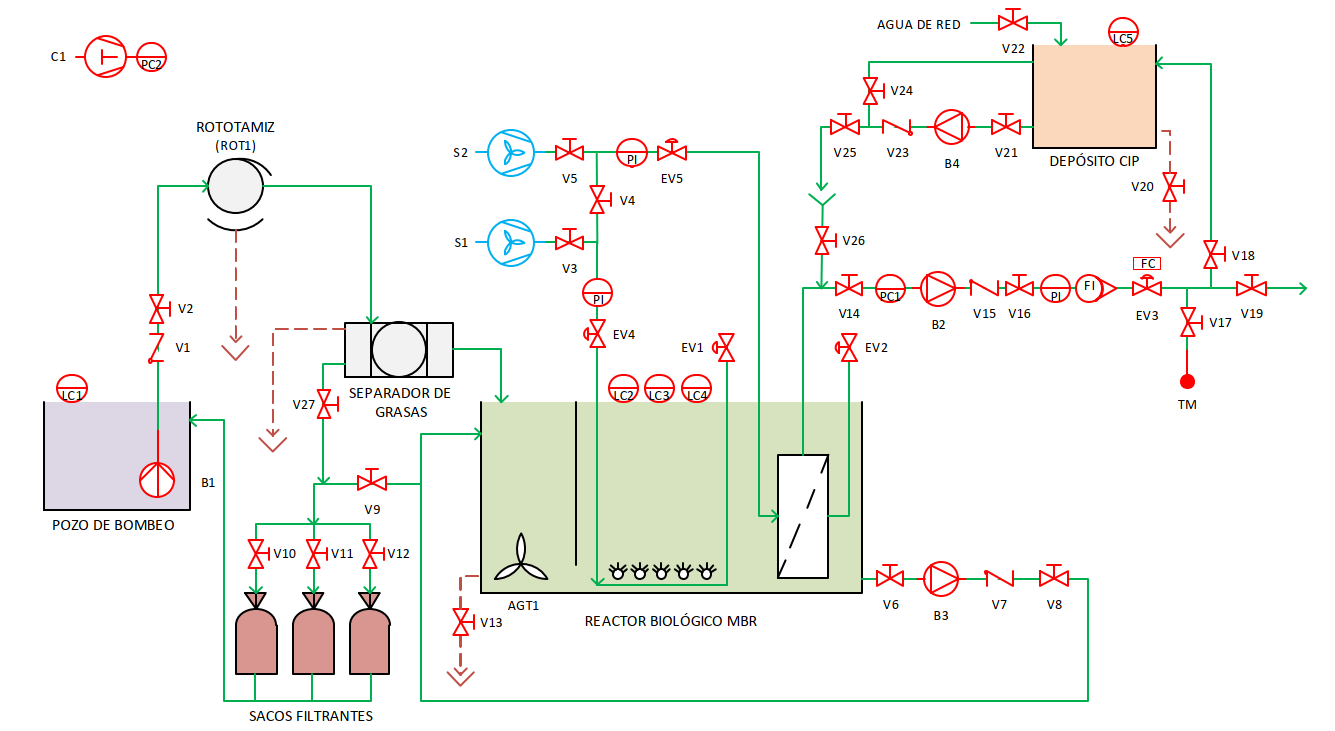

MBR process scheme

COMPARISON BETWEEN THE ETARES / LAGOONS / TANKS SYSTEM AND THE DAYO SYSTEM

| ETARES / LAGUNAJES / TANKS | DAYO UF SYSTEM | |

|---|---|---|

| Construction work | Total build from scratch | Only the well and the support base |

| The area to be occupied | High | Minimum |

| The quality of the outlet water | Does not meet the download standards | Comply with sanitary / discharge regulations |

| Recycling | Legally, not possible | Complies with sanitary values / regulations |

| % Recycling | 0% | 80-90% |

| Extraction of sludge / liquids | Manual, emptying the pond | Automatically and with semi-dry looking filter bags |

| Power Consumption | Light | Medium (Renewable Energy) |

| Transportability | Fixed installation | Mobile / Transportable |

| Extension | Not possible | Anything you need |

| Control and supervision | Requires labor | It’s completely automatic |