Penstocks and Sluice Gate PTR

Penstock, sluice gate, water gate are mostly used to block and control the water flow, and water level in rivers, channels, intake structures and water reclamation, but they are widely used also in wastewater treatment plants, where treatment and cleaning of water are proceed.

All the penstocks, sluice gate and water gate of manufacturing SEFT are made by stainless steel AISI 304L or AISI 316L with special care at the choice of the raw material, as much as at the surface finishing quality. SEFT manufacure penstocks both on catalogue and on customer request with internal project, and even for big dimensions and high hydraulic load. Every product is designed and dimensioned with attention.

All the penstocks and sluice gate are in accordance with DIN 19569 / BS 7775 / EN12266

The penstocks and Sluice Gate are installed in natural or artificial channels or above a pipes in order to intercept the water flow. The closed position is achieved when the slide reach the lower position. The opening is obtained lifting up the slide from the lower position. The flowing area is delimited by the lower side of the slide and the bottom of the pipe or of the channel.

The most common constructive solutions can be the insertion across a channel, or plugged on a wall, usually this last solution is suitable for pressure water flow. The frame can be as a gate, or with independent operating column, they can be manually activated or by an electrical actuator. In order to limit the torque required for the open/close operations, a geared reducer can be applied.

Shredder for powder and granulate TRT

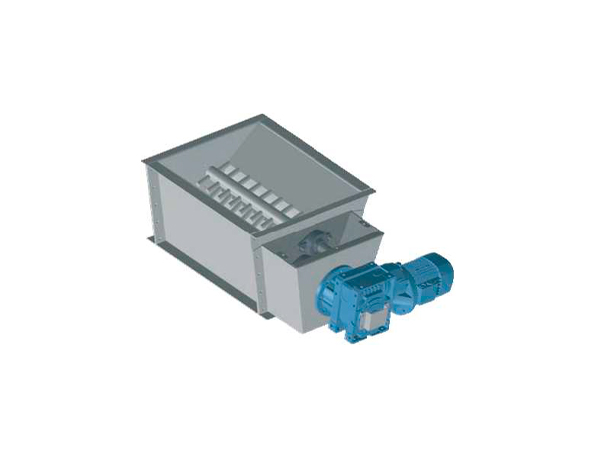

The Shredder or Grinder model TRT consists of a square section body with upper and lower flanges, horizontal rotating shafts with poles or blades, a retaining grid and 4 end brackets complete with sealing units.

It represents the ideal solution for the breakage of lumps created in the production processes or transport of dusty / granular and friable materials. The fast rotation of the poles (or blades) through a fixed grid causes grinding of the lump, the presence of two rotors at different speeds allows high flow rates.

The Shredder or Grinder model TRT is available in carbon steel, stainless steel AISI 304L or 316L

Fixed or variable motor, with chain or gear transmission, customizable.

Advantages:

– tough

– modular design

– compact size

– easy installation

Concrete Reclaimer Systems DTR

The concrete reclaimer is a machine used in precast concrete plants and for the recovery of the aggregates. The particles of inert materials with a size greater than 0.3 mm are separated from the washing water by the screw of extra-heavy construction. Heavy carbon steel galvanized.

Available in:

– Version with large hopper for unloading of two mixers simultaneously

– Version with small hopper to the discharge of a single mixer

– Mini-course for small separator

The separator is so defined by the ability to wash and separate the aggregates (gravel used to build the cluster) of cement and silt. This makes the material from washing concrete mixers fully reusable. In addition the DTR is a machine very reliable and easy to maintain.

Slide Gate Valve SV

Slide valves, or guillotine valves, are used to intercept and dose material flows, dust or granules by gravity from silos, hoppers or containers as well as transporting them.

Section: square or rectangular

– Square SVQ: 150 to 600

– Rectangular SVR: 150 to 600

Material:

– Carbon steel painted or stainless steel AISI 304L – 316L

Operation:

– Manual, pneumatic or motorized

Volumetric Dosing DV

Screw Dosing System

Specific for dosage of flocculant and polyelectrolyte in water treatment application, for the conditioning and mechanical dehydration of the sludge to be treated inside the purification plants.

There are various accessories as:

– Filling hopper of different sizes

– Capacitive gauge

– Motorvibrator for shaking

Polymer Dosing Station SPP

Automatic polymer dosing preparation systems to dissolve and dilute powder and emulsion needed at the conditioning and mechanical dehydration of the sludge to be treated inside the purification plants, SEFT proposes an automatic station is polyelectrolyte polypreparing machine for the continuous preparation of the fluocculant substances necessary to complete the chemical / physical process that favors the dewatering of the sludge.

– Operation:

– The powdered polyelectrolyte stored in a hopper is transported by a screw conveyor, and dosed in a first sector of the dilution tank, where it is appropriately diluted with water thanks to the action of an electromechanical agitator which favors its dissolution. At the end of this first phase the solution passes into a second sector to complete the preparation, to then conclude the process in a third sector of maturation, and be ready for use.

– Same process for the preparation of the polyelectrolyte from a liquid concentrate takes place, instead of the powder doser a dosing pump is installed. Combined system liquid / powder systems allow maximum flexibility of use, also on the same equipment

-The passage between the various internal sectors of the tank is managed and controlled by a system of communicating vessels that automatically interrupt or resume its function once the desired level is reached by sector, this process is controlled and automated by an automated PLC electrical control panel.

Lime Milk Dissolvent

It consists of a cylindrical tank where the lime and water are placed: by a stirring paddle, the lime milk is acquired.