Septage Receiving Station in wastewater treatment

Septage Receiving Station Unit STV/C

SEPTAGE RECEIVING STATION

design and manufacturing ability of SEFT with the realization of product that can be customized in all parts to be satisfaction each customer request.

STV/C is a unit compact able to carry out the pre-treatment of screening of wastewater from industrial processes of various types. Before they are released in wastewater treatment plants.

The entrance is equipped with a quick attack (Perrot type) and an electromechanical valve.

The wastewater discharged directly from the tanker, is filtered by a screw screen that removes the solids that are then drained and compacted and then discharged into a bin or bagged.

Functions of Septage Receiving Station:

– Screen – Filtration

– Fecal sludge treatment

– Sludge dehydration / compaction of the solid removed

Advantages of Septage Receiving Station:

– Equipment Customized

– No odor

– No pumps

– No obstructions

– Low operating costs and maintenance

– Compact equipment

– Construction work is not necessary

– Low residual content of organic matter

– Reduction up to 40% volume of the solid removed

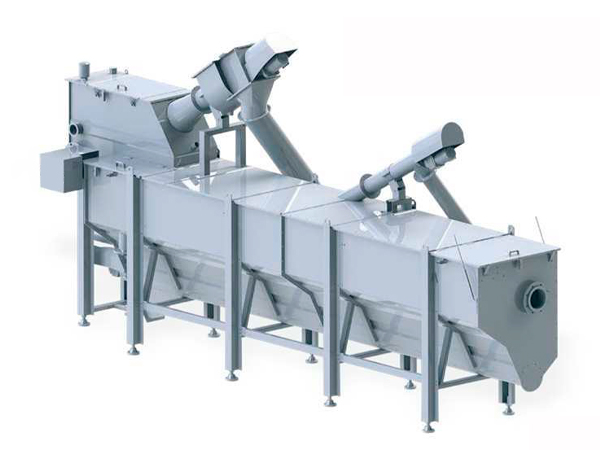

Pre-treatment Combined Compact Unit STV/T

This combined machine is fed by a pump or to gravity, through a fixed pipe, the effluent passes through a screw screen that removes the most large solid particles, then goes to a sedimentation tank where the particles sedimented are then removed by a system of scews.

As an option you can install the system for removal of fats and suspended oils.

Features:

– Filtration / Screening

– Wash / compaction of solids removed

– Extraction of sand

– Degreasing (on GDF/D version)

Advantages:

– No odor

– No mechanical parts in contact with the sewage

– Low erection and maintenance costs

– No hanging bears

– Possibility of sand washing before discharging

– Completely close machine

– Low operating costs and maintenance

– Reduced space requested

– Construction work is not necessary

– Ease of installation and management

– Low organic matter in the solid residue extracted

– Reduction up to 40% in volume of solids removed

Pretreatment plants

Combined Pretreatment Compact Unit GDF/D Design and manufacturing

This Combined Pretreatment Compact Unit equipment is fed by a pump or to gravity, through a fixed pipe. The effluent passes through a screw screen that removes the most large solid particles, then goes to a sedimentation tank where the particles sedimented are then removed by a system of scews. As an option you can install the system for removal of fats and suspended oils.

Features Combined Pretreatment Compact Unit:

– Filtration – Screens

– Wash and compaction of solids removed

– Extraction of sand – grit

– Degreasing (on GDF/D version)

Advantages Combined Pretreatment Compact Unit:

– No odor

– Low operating costs and maintenance

– Reduced space requested

– Building work is not necessary

– Ease of installation and management

– Low organic matter in the solid residue extracted

– Reduction up to 40% in volume of solids removed

Compact Unit Pretreatment Plants VSD Design and manufacturing

Combined equipment able to perform two functions simultaneously:

– Grit – sand whasing process

– Grit – sand removal process

– Oil and degreasing removal

The effluent is fed to the machine through a fixed pipe and decants in the tub, the sands are then removed by a system of augers, while fats and oils surface are removed from the system of deoiling by an air blowing.

Combined Wastewater pre-treatment Unit GDE/D Design and manufacturing

PRE-TREATMENT COMBINED UNIT: SEFT MANUFACTURING EQUIPMENTS FOR SCREENING, DEGRITTING AND MANUAL REMOVING OF OILS AND FATS

The GDE/D model performs: screening, sand removal, fat and grease manual removing.

GDE o GDE/D could be supplied in 2 models:

1 – Grit removal + Screw screen with perforated sheet or wedge wire.

2 – Sand classifier + Rotary drum filter wedge wire profile.

Based on the chosen model, pre-treatment combined unit, you can get it will be possible to get a different type of screening, the sewage goes through the screening section for the solid parts removal, then the sewage falls down a decantation tank where the particles go down, here an extraction spiral screen removes them.

Advantages of Combined Wastewater treatment Unit:

– Odor free

– No clogging

– Low maintenance and operation costs

– Low room needed

– No construction works needed

– Easy to install and operate

– Low residual organic content in the washed out solid

– Volume reduction (up to 40%) of the washed out solid

– Sand removal: >=90% of particles up to 200 μ