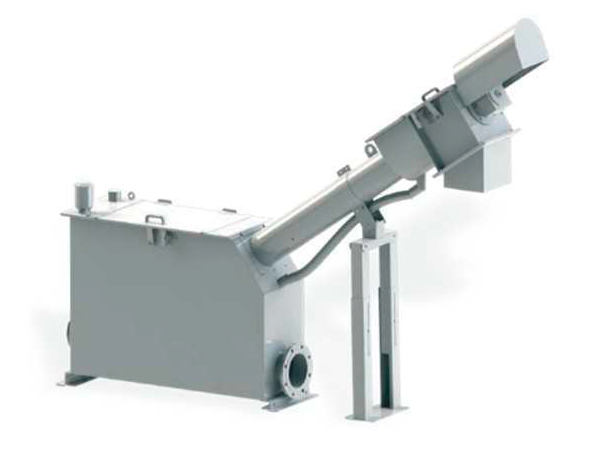

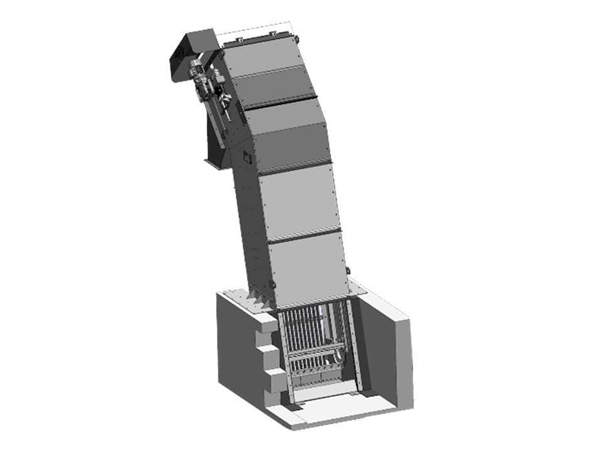

Screw screen compactor FCP

Combined machine for the separation and compaction of solid present on the waste water coming from municipal and industrial plants of various kinds.

The Screw screen compactor:

– Loading basket:

– Drilled sheet or wedge wire

– Transport section: tubular or U-section

– Compaction and discharging section

– Adjustable feet

The compactor is located in the upper part of the machine at the end of the transport section, carries out the compaction/dehydration of the solid to reduce the weight and the volume.

Advantage of screw screen compactor:

– Installation directly in the channel

– Low speed of rotation and no intermediate supports

– Self-cleaning with brushes fit on the screw

– Low maintenance and low initial investment

– High percentage of solid removed

When required, the compactor is installed in the upper part of the screw conveyor at the end of the grating transport area and performs the compaction and dehydration of the solid to reduce its weight and volume up to 50%

Screw Screen Filter wastewater treatment FC

The Screw Screen Filter is combined machine and equipment customizable for the separation of solids present in the wastewater treatment coming from municipal and industrial plants of various kinds.

The Screw Screen Filter is composed by:

– Loading basket: drilled sheet or wedge wire

– Transport section: tubular or U-section

– Discharging section

– Engine and gearbox

– Adjustable feet

– The technical features are the same of the one used in the FCP model.

Advantages for Screw Screen Filter:

– Installation directly in the channel

– Low speed of rotation and no intermediate supports

– Self-cleaning with brushes fit on the screw

– Low maintenance and low initial investment

– High percentage of solid removed

When required, the compactor is installed in the upper part of the screw conveyor at the end of the grating transport area and performs the compaction and dehydration of the solid to reduce its weight and volume up to 50%

Screw Screen with Compactor

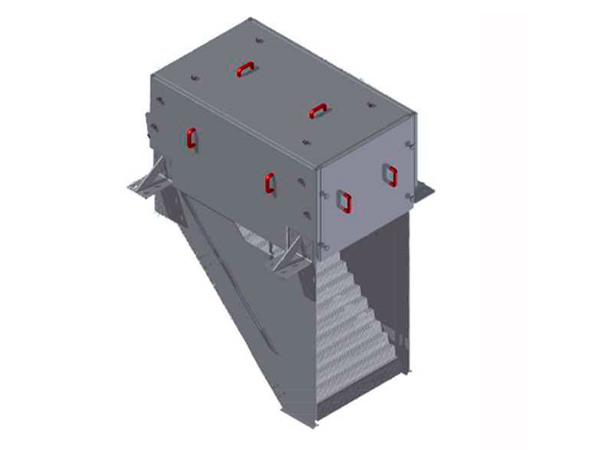

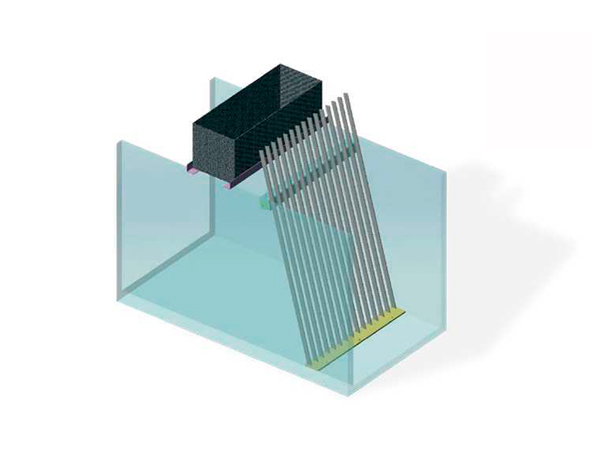

Screw Screen Compactor in tank FCP/C

The Screw screen in tank is equipped with fully sealed stainless steel container or tank to allow installation where there is not provided a concrete channel.

The container / tank is complete with flanged stub pipe of input and output, the container / tank can have a cassette side bypass rake screen (optional).

At the end of conveying section is assembled the compactor with the related discharge mouth.

Same principle of operation of the series FC, with the simple addition of the container.

Advantage of Screw screen in tank:

– Custom project

– High percentage of solid removed

– Low speed of rotation and no intermediate supports

– Self-cleaning with brushes fit on the screw

– Low maintenance and low initial investment

When required, the compactor is installed in the upper part of the screw conveyor at the end of the grating transport area and performs the compaction and dehydration of the solid to reduce its weight and volume up to 50%

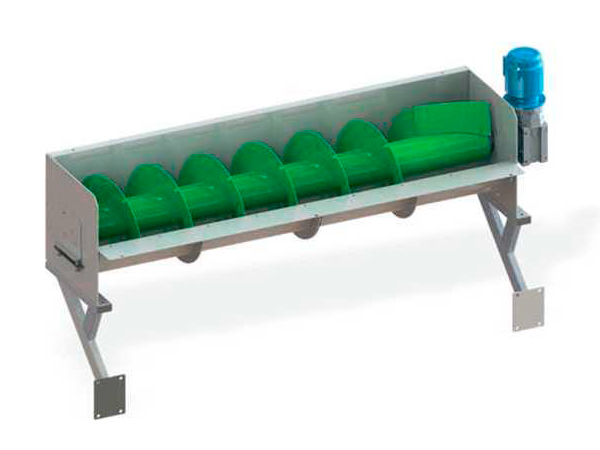

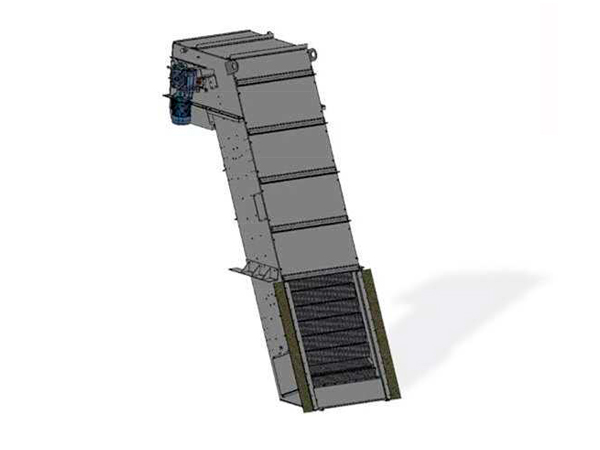

Screw Screen for High Solid Content Flows FC/U

Screw Screen for High Solid Content Flows – model FC/U by SEFT, is used for the treatment of wastewater with a significant percentage of solid to separate.

Differs from the other screw screens for a section of transport realized with U-trough and a discharging section of considerable size. In the lower part is positioned the loading basket. The screw is shaft-less but greatly reinforced. The machine can be positioned inside a channel or in a special tank

Advantages Screw Screen for High Solid Content Flows:

– High percentage of solid removed

– Low speed of rotation and no intermediate supports

– Self-cleaning with brushes fit on the screw

– Low maintenance and low initial investment

– Considerable reduction of volume and weight at the end of processing (up to 35-40%)

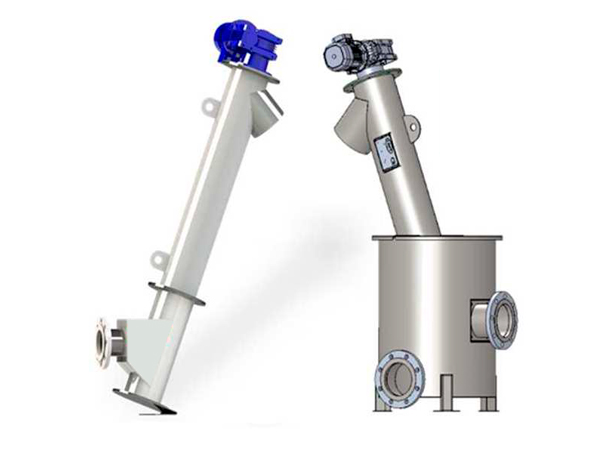

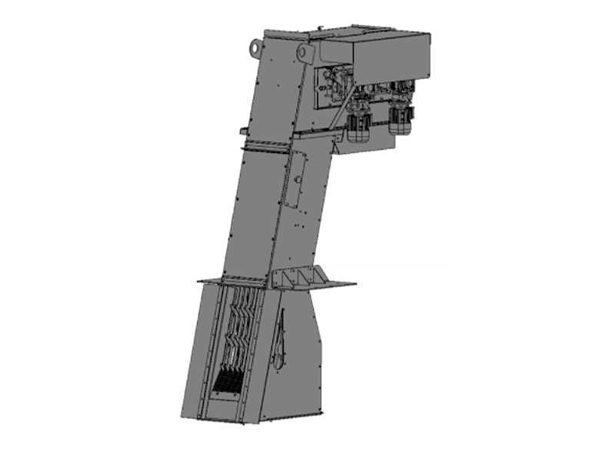

Vertical Screw Screen Compactor FCP/V

Vertical Screw Screen with compactor, SEFT manufacturing all machines customized.

Vertical machine for combined screening, lifting and compaction of the solids present in wastewater treatment. The screw screen intercepts directly the channel or the piping of arrival of water to treat

Composition Vertical Screw Screen Compactor:

– A tubular transport section.

– A loading zone with cylindrical or semi cylindrical screen connected to the inlet pipe.

– A discharging section with or without compactor.

– The liquid grilled exits from the basket kept clean by the brushes in nylon bolted on the surface of the screw, while the solids are extracted and discharged.

– The length of the transport section is variable according to the needs and is available a wide range of holes of filtration.

Advantages Vertical Screw Screen Compactor:

– Customized equipment

– High percentage of solid removed

– Low speed of rotation and no intermediate supports

– Self-cleaning with brushes fit on the screw

– Low maintenance and low initial investment

– Considerable reduction of volume and weight at the end of processing (up to 35-40%)

When required, the compactor is installed in the upper part of the screw conveyor at the end of the grating transport area and performs the compaction and dehydration of the solid to reduce its weight and volume up to 50%

Compact Screw Screen with Tank CSS/C

The Compact Screw-Screen with tank model CSS/C is an economic solution, equipment designed for a solids separation in the domestic effluent and to block and to collect the material present at the same time and it permits to improve the overall performance of the wastewater treatment system before.

It’s possible to use the CSS/C also for other industrial and municipal applications, but in this case please contact us and follow our recommendation and supervisioning of our technicians.

Thanks to the special design and inclination the CSS is studied for a perfect and “plug & play” installation for: channels, wells and artificial pools.

It’s very easy to connect it directly at the existing pipe through a “commercial” flange (DN-PN).

Available in 2 models:

– Compact Screw-Screen with tank CSS/C 168

– Compact Screw-Screen with tank CSS/C 219

– Filtration’s range: from 3 up to 6 mm

– Volume reduced of 40% approximately

– Inlet flange dimension: DN100-DN150 PN10

– Flow rate: 16-20 m3/h with municipal-domestic wastewater (for other applications, contact us)

Rotary Screw Screen Compactor FCR

This combined equipment is used for the separation and subsequent dewatering and compacting of the solid content in wastewater coming from industrial and municipal plants.

Rotary Screw Screen Compactor is composed by:

– Loading basket

– External structure in stainless steel AISI 304L or 316L

– Screw in high carbon steel or stainless steel

– Filter Perforated sheet metal or Wedge Wire

– Transport section: tube or U-shape trough

– Discharging section: with compactor

– Driver and gear reducer

– Supporting adjustable foot

– Outer rotary loading drum concentric to the loading basket

The solid in the sewage enters in the basket occluding it, bringing an increase of the level before the filter. A level sensor sends a signal to start the rotation of the screw screen and consequentely of the outer rotary loading drum. During rotation the outer rotary loading drum discharges solid in the screw conveyor with the aid of outer rotary loading drum washing system. The outer surface of the screw screen is further cleaned by brushes fixed on the outer side screw so that makes cleaning action during rotation. The compactor located at the end of the transport section, on top of the machine, makes compaction and dehydratation of solid, to reduce weight and volume.

Advantages of Rotary Screw Screen Compactor:

– Equipment Customized

– Fine and coarse screening

– High percentage of solid removed

– Low speed of rotation and no intermediate supports

– Self-cleaning with brushes fit on the screw

– Low maintenance and low initial investment

– Considerable reduction of volume and weight at the end of processing (up to 50%)

Overflow Spillway Water GPS

The screening equipment model GPS is used in water treatment as first rain or as water treatment is relief in case of heavy rainfall, the installation of Overflow Spillway Water is ideal for mechanical screening material floating in overflows in situations of “overflow”.

The Overflow Spillway Water is composed by:

– A filtering surface curved in a semicircle

– A rotating transport screw

– A zone of calm for the discharge of screenings collected

The loading basket is composed by a stainless steel sheet perforated and by an adeguate support structure of the machine, the screw that rotates inside of it transports the residues of sifting captured by the filter in the axial direction towards the discharge zone of the solid. The special brushes mounted on the surface of the screw keep clean the filter and ensure a perfect cleaning of the holes of passage of the waters. The start/stop cycle of the screw is managed by a level indicator placed at the end of the machine.

The discharge zone is composed by a zone of calm where the collected material is ejected from the machine by means of a special pallet placed at the end of the screw. The gear motor placed at the end of the machine is compact in size and is sized based on the length and the diameter of the machine.

Advantages Overflow Spillway Water:

– Design customized

– Low speed

– Fully automatic operation

– Low maintenance thanks to the self-cleaning brushes

– Adaptable to existing systems

– High percentage of removal of solid

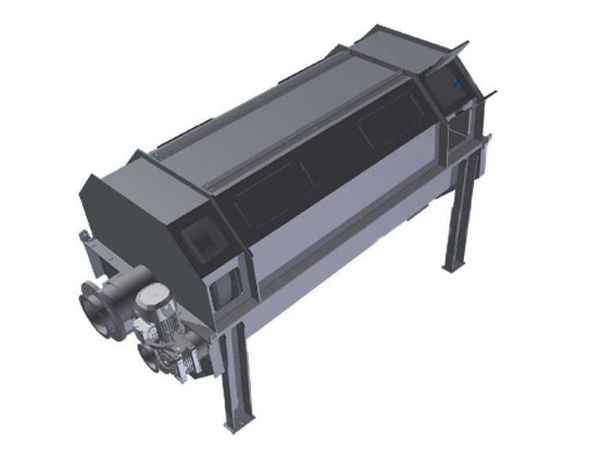

Rotating Filtering Drum GRR

The Rotating Filtering Drum model GRR is equipment of stainless steel case with a drum filter made of wedge wire rotating in.

The wastewater flows inside the feeding tank through a flanged spout and it is conveyed on the external surface of the filtering drum by a special distributor.

The cleaned water get through the filtering surface toward the outlet spout, while the solid particles remain on the rotary drum surface and they are subsequently removed by a fix blame placed at the opposite side of the drum.

The filtering is kept clean by a washing system. The filtering part is ready to repeate the cycle at every turn since it is particleless.

Advantages of Rotating Filtering Drum:

– Equipment Customize

– Built entirely of stainless steel AISI 304L – 316L

– Compact size Low maintenance

– Self-cleaning

– Drum: with wedge wire 0,25mm

Internally Fed Rotary Drum Screen IFS

The internally fed rotary drum screen IFS is composed of a tank and a spiral connected to a drum for the screening transportation.

The drum screen is made of a perforated plate and the perforated holes profile diameter can be selected on the customer’s needs.

The drum screen is supported by nylon wheels, and it is operated by a gearbox. The filter is fed through a nozzle placed in the front of the machine.

A diffuser spreads the water on a large area of the screen which, rotating, separates water from the organic particles contained.

The filter is cleaned through a washing system consisting in a tube with spray nozzles for pressurized water.

During equipment operation, the water is conveyed at the outlet placed in the front of the machine, while the screenings are transported by the spiral towards the screening outlet in the back of the machine.

The screen inclination contributes to the dewatering of screenings, the screen is also equipped with a by pass pipe to avoid overflows with a predisposition for a overflow sensor.

Advantages of Internally fed rotari drum screen:

– Customized equipment

– Improved double washing system equipped with high performance nozzles.

– Easy maintenance support wheels, replaceable without having to remove the filtration cylinder.

– Special chain drive system that does not require tensioning adjustment, for a higher durability over time and stability of performance.

Bar Screen CRS

Wastewater Bar Screen

– The coarse screening is the first operation that must be performed in a civil and industrial wastewater treatment plant. For these needs SEFT proposes The CRS model which is a bar screen composed of fixed bars and a rake / comb for separation the screening material.

– This system of screening has the purpose of intercepting and subsequently eliminating the solids of high dimensions that could damage or slow down the purification processes and the equipment of the plant or obstruct the pipes, and is particularly important upstream of the lifting stations, for protect the electric pumps.

– The bar screen, comb or chain rake, is equipment designed for the coarse screening of sewage entering the purification plants, the filtration, or bar thickness, is chosen according to the type and quantity of material and considering the depurative process scheme adopted.

– The filtering screen is a fixed bar screen, this machine is able to block the material in suspension, lift them out of the water flow, by means of the cleaning combs o rake, and convey them to the drain placed in the upper part of the machine, in the unloading area a mechanical cleaning system causes the collected material to fall a container.

Fine Screening BLT Self Cleaning Automatic Roughing Screen

It is a continuous automatic screen for fine solids roughing, it is self-cleaning, it is composed of a vertical conveyor belt formed by filter elements in technopolymer reinforced with fiberglass for high mechanical and thermal performance, the operation of the screen is rotary and what does not pass through the filter grid is collected and discharged from the discharge mouth located in the upper part of the machine, the “multi-rake” filter elements guarantee a high collection of the material to be separated. </ div>

Step Screen GPG

Step Screen, is equipment used for the solid-liquid separation operations, as a system for the mechanical separation of grits, detritus and floating solids. Its typical field of usage is in the wastewater treatment plants, where an effective primary screening is the best way to achieve efficiency in the following processes

Main features of Step Screen:

– Customized equipment

– Series of laminas with a step design

– Available in stainless steel AISI 304L or 316L

– Simple and robust construction

– Absence of overly complicated referral

– No chains or deformable quadrilaterals

All transmission systems, bearings, shafts and couplings are out of the channel (no contact with the treated fluid and easy maintenance)

The cover is designed to protect the step screen till the channel border, protecting also the moving parts from the weather (allowing open air installations and acting as a CE-norm protection system for the safety of plant personnel)

The filtering unitis divided in two interpenetrating blocks, one mobile and one steady, whose relative movement produces a steady going of the filtered solids towards the discharge, leaving the filtering spaces always free and clean. Furthermore, the deposit of the solid particles on the screening bed can be used to improve the percentage of removed floating debris.

When choosing the filtration spacing, must be took into account the wide filtering surface that allows to work with low fluid speed through the grid, reducing the resulting headloss.

Perforated Mesh Vertical Screen GSM

The screening process is first operation to be considere in a municipak or industrial wastewater treatment plant, it has the purpose of intercepting and eliminating high-strength solids that could damage or slow down purification processes and plant equipment and hinder pipelines.

Particularly important is to protect the electric pumps, this equipment Perforated Mesh Vertical Screen model GSM is specially designed for medium or fine screen of slurries entering the plants.

The filtration is chosen based on the type and quantity of the material envisaged and in accordance with the scheme of the purification process adopted. Thanks to the perforated filter, this equipment can block the suspended bodies (larger than the light filtration), lift them from the water flow thanks to the rotation of the catenary and transport them to the exit prepared in the upper part of the grid.

This equipment is self-cleaning with washing nozzles and brush systems positioned in the upper part of the machine which make it possible to have a clean mesh with each rotation.

Manual Bar Screen GCM

The manual bar screen is equipment of a fixed grid to be installed on a reinforced concrete channel, cleaning is performed manually with a rake to remove the waste material and place it in a container at the top end of the screen.

According to specific needs, an operator must periodically clean the deposited material using the rake.