Industrial heating

You are here:

- Home

- Products and services

- Ventilation and industrial heat

- Industrial heating

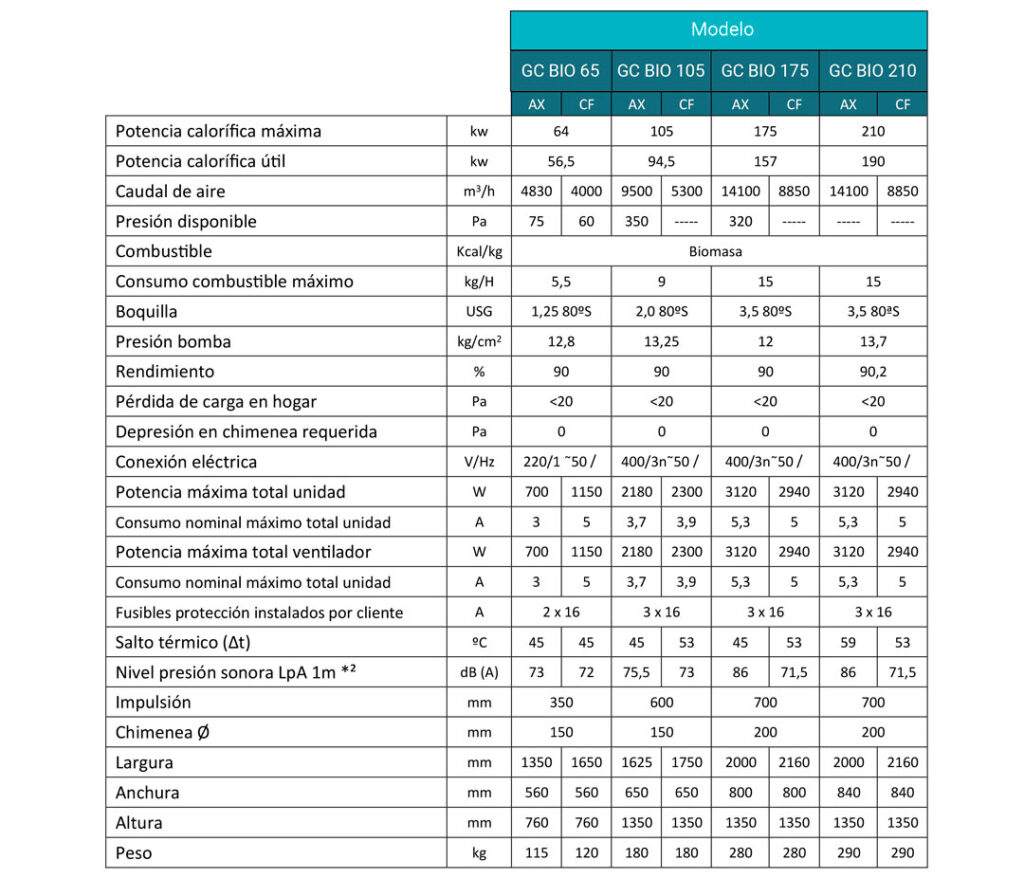

Our partner is a manufacturer of industrial hot air generators, and its strategic orientation is green and clean energy and in particular biomass as an ecological fuel so that it can power all its produced equipment.

In its manufacturing area, the company is firmly committed to training its employees so that they can develop their own equipment. Throughout their existence they have invested in technological innovation as one of the most important parts of their activity.

Industrial hot air generators are prepared to heat large surfaces, such as buildings, greenhouses, drying greenhouses, livestock farms and industry, with the use of biomass as a green and clean fuel, available on the market.

Fuel: Biomass

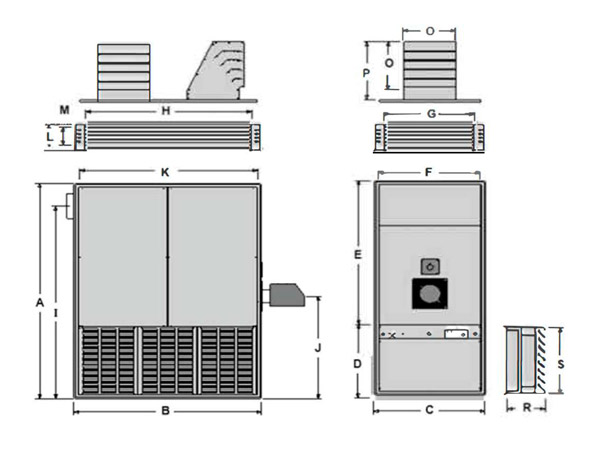

Tubular heat exchanger and combustion chamber in refractory stainless steel (Aisi 310)

High temperature fan with jet blades

Enclosure panels internally insulated with rock wool (100kg / m3)

Maximum 250ºC continuously

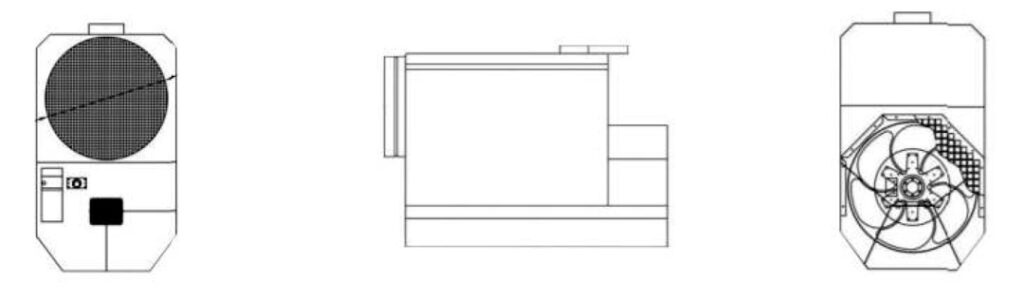

Aspiration and impulsion ear mouthpiece

Union via circular duct not included * (depends on the installation)

External power control box

Exterior finish in oven-dried pre-lacquered paint

Outdoor fans. As an option Fans model 2271