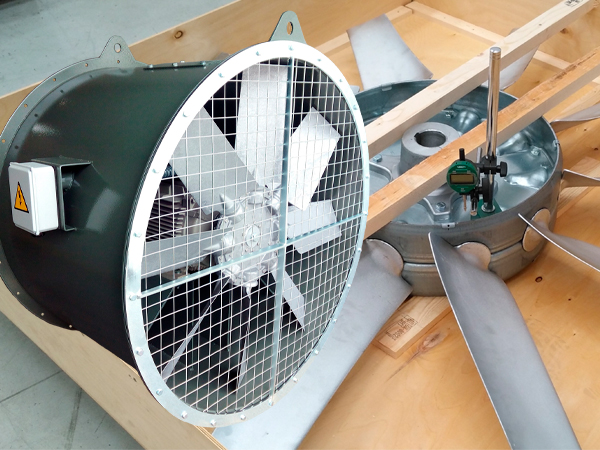

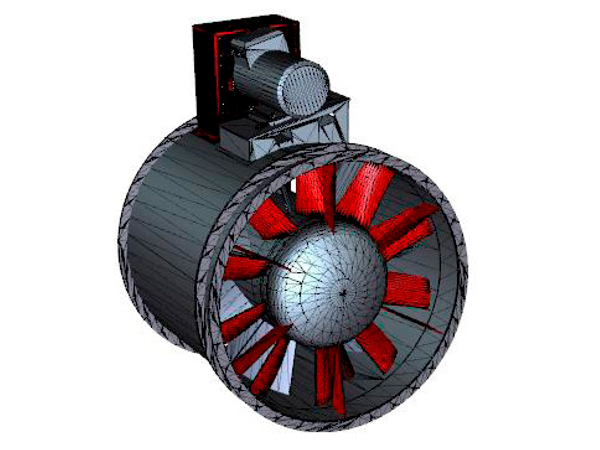

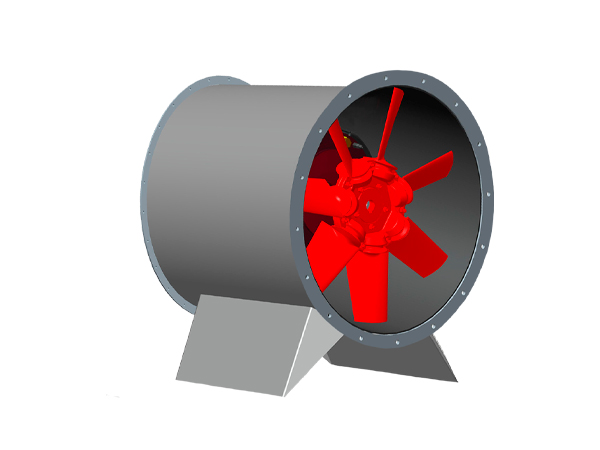

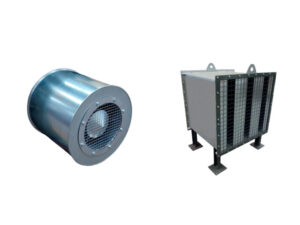

Our associate manufactures axial fans, made to measure, and of high performance, being highly efficient products that favor energy savings, especially in large industrial plants.

They have state-of-the-art technology and a team of experts in the sector that allows them to manufacture high-quality axial fans. Thanks to its innovative design and the use of high quality light and resistant materials, we can offer a robust, compact and very quiet construction that adjusts to the needs of the client.

Its axial fans, with aluminum, polyamide or polypropylene propellers depending on the fluid to be transported, are designed for severe working conditions and for applications such as extraction of vapors, fumes, ventilation of buildings, cooling in furnaces, etc.

The working range in terms of flow rates and pressures is very wide, being able to reach temperatures of 110ºC under normal conditions, and with special designs that allow this temperature to be exceeded.

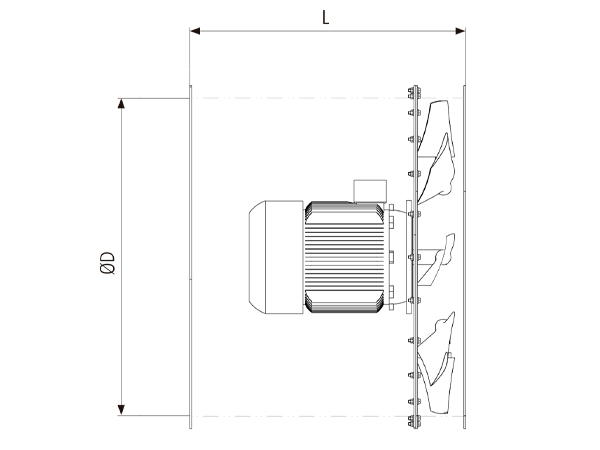

| MODEL | DIAMETER (D) | L | WEIGHT (kg) |

|---|---|---|---|

| AX | 300 | 270 | 21 |

| AX | 350 | 320 | 25 |

| AX | 400 | 360 | 28 |

| AX | 450 | 410 | 32 |

| AX | 500 | 450 | 35 |

| AX | 550 | 500 | 39 |

| AX | 600 | 540 | 42 |

| AX | 650 | 590 | 46 |

| AX | 700 | 630 | 49 |

| AX | 750 | 680 | 53 |

| AX | 800 | 720 | 112 |

| AX | 850 | 770 | 119 |

| AX | 900 | 770 | 126 |

| AX | 950 | 810 | 133 |

| AX | 1000 | 850 | 140 |

| AX | 1050 | 890 | 147 |

| AX | 1100 | 940 | 154 |

| AX | 1150 | 980 | 161 |

| AX | 1200 | 1020 | 168 |

| AX | 1250 | 880 | 313 |

| AX | 1300 | 910 | 325 |

| AX | 1350 | 940 | 338 |

| AX | 1400 | 980 | 350 |

| AX | 1450 | 1010 | 363 |

| AX | 1500 | 1050 | 450 |

| AX | 1550 | 1090 | 465 |

| AX | 1600 | 1120 | 480 |

| AX | 1650 | 1160 | 495 |

| AX | 1700 | 1190 | 510 |

| AX | 1750 | 1230 | 525 |

| AX | 1800 | 1260 | 540 |

| AX | 1850 | 1300 | 555 |

| AX | 1900 | 1330 | 570 |

| AX | 1950 | 1370 | 585 |

| AX | 2000 | 1400 | 600 |

| AX | 2050 | 1440 | 615 |

| AX | 2100 | 1470 | 630 |

2: La longitud puede cambiar en función de la longitud total del motor

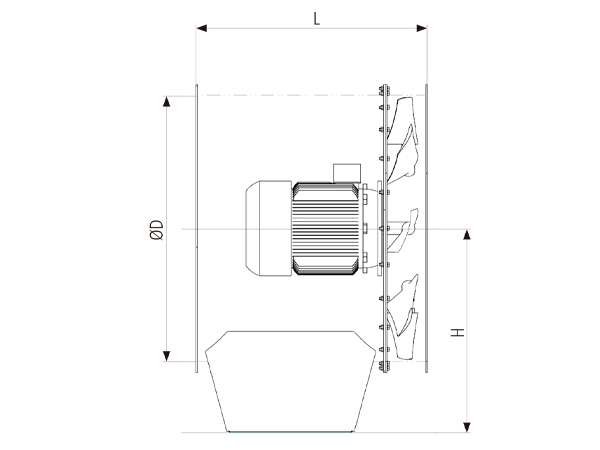

| MODEL | DIAMETER (D) | L | H | WEIGHT (kg) |

|---|---|---|---|---|

| AX | 300 | 270 | 250 | 31 |

| AX | 350 | 320 | 280 | 35 |

| AX | 400 | 360 | 300 | 38 |

| AX | 450 | 410 | 330 | 42 |

| AX | 500 | 450 | 350 | 45 |

| AX | 550 | 500 | 380 | 49 |

| AX | 600 | 540 | 400 | 52 |

| AX | 650 | 590 | 430 | 56 |

| AX | 700 | 630 | 450 | 59 |

| AX | 750 | 680 | 480 | 63 |

| AX | 800 | 720 | 500 | 122 |

| AX | 850 | 770 | 530 | 129 |

| AX | 900 | 770 | 550 | 136 |

| AX | 950 | 810 | 580 | 143 |

| AX | 1000 | 850 | 600 | 150 |

| AX | 1050 | 890 | 630 | 157 |

| AX | 1100 | 940 | 650 | 164 |

| AX | 1150 | 980 | 680 | 171 |

| AX | 1200 | 1020 | 700 | 178 |

| AX | 1250 | 880 | 730 | 323 |

| AX | 1300 | 910 | 750 | 335 |

| AX | 1350 | 940 | 780 | 348 |

| AX | 1400 | 980 | 800 | 360 |

| AX | 1450 | 1010 | 830 | 373 |

| AX | 1500 | 1050 | 850 | 460 |

| AX | 1550 | 1090 | 880 | 475 |

| AX | 1600 | 1120 | 900 | 490 |

| AX | 1650 | 1160 | 930 | 505 |

| AX | 1700 | 1190 | 950 | 520 |

| AX | 1750 | 1230 | 980 | 535 |

| AX | 1800 | 1260 | 1000 | 550 |

| AX | 1850 | 1300 | 1030 | 565 |

| AX | 1900 | 1330 | 1050 | 580 |

| AX | 1950 | 1370 | 1080 | 595 |

| AX | 2000 | 1400 | 1100 | 610 |

| AX | 2050 | 1440 | 1130 | 625 |

| AX | 2100 | 1470 | 1150 | 640 |

2: La longitud puede cambiar en función de la longitud total del motor

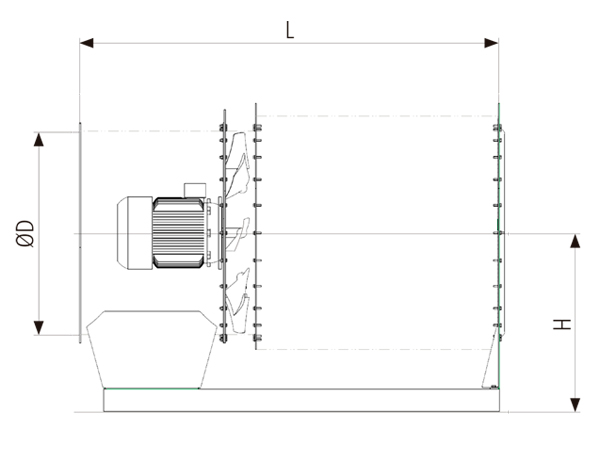

| MODEL | DIAMETER (D) | L | H | WEIGHT (kg) |

|---|---|---|---|---|

| AX | 300 | 750 | 390 | 55 |

| AX | 350 | 880 | 420 | 63 |

| AX | 400 | 1000 | 440 | 70 |

| AX | 450 | 1130 | 470 | 78 |

| AX | 500 | 1250 | 490 | 85 |

| AX | 550 | 1380 | 520 | 93 |

| AX | 600 | 1500 | 540 | 100 |

| AX | 650 | 1630 | 570 | 108 |

| AX | 700 | 1750 | 590 | 115 |

| AX | 750 | 1880 | 620 | 123 |

| AX | 800 | 2000 | 640 | 186 |

| AX | 850 | 2130 | 670 | 197 |

| AX | 900 | 2210 | 690 | 208 |

| AX | 950 | 2330 | 720 | 219 |

| AX | 1000 | 2450 | 740 | 230 |

| AX | 1050 | 2570 | 770 | 241 |

| AX | 1100 | 2700 | 790 | 252 |

| AX | 1150 | 2820 | 820 | 263 |

| AX | 1200 | 2940 | 840 | 274 |

| AX | 1250 | 2880 | 870 | 423 |

| AX | 1300 | 2990 | 890 | 439 |

| AX | 1350 | 3100 | 920 | 456 |

| AX | 1400 | 3220 | 940 | 472 |

| AX | 1450 | 3330 | 970 | 489 |

| AX | 1500 | 3450 | 990 | 580 |

| AX | 1550 | 3570 | 1020 | 599 |

| AX | 1600 | 3680 | 1040 | 618 |

| AX | 1650 | 3800 | 1070 | 637 |

| AX | 1700 | 3910 | 1090 | 656 |

| AX | 1750 | 4030 | 1120 | 675 |

| AX | 1800 | 4140 | 1140 | 694 |

| AX | 1850 | 4260 | 1170 | 713 |

| AX | 1900 | 4370 | 1190 | 732 |

| AX | 1950 | 4490 | 1220 | 751 |

| AX | 2000 | 4600 | 1240 | 770 |

| AX | 2050 | 4720 | 1270 | 789 |

| AX | 2100 | 4830 | 1290 | 808 |

2: La longitud puede cambiar en función de la longitud total del motor

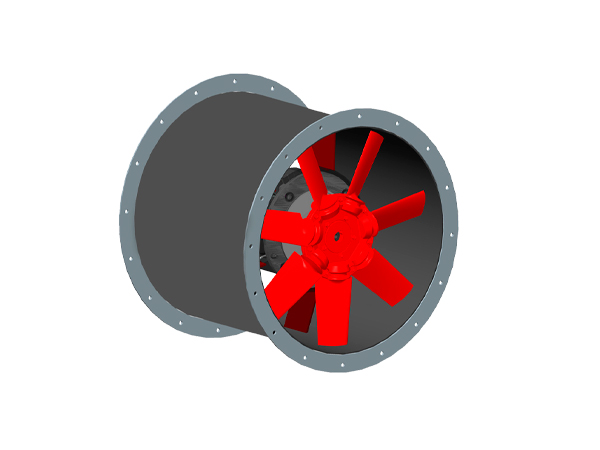

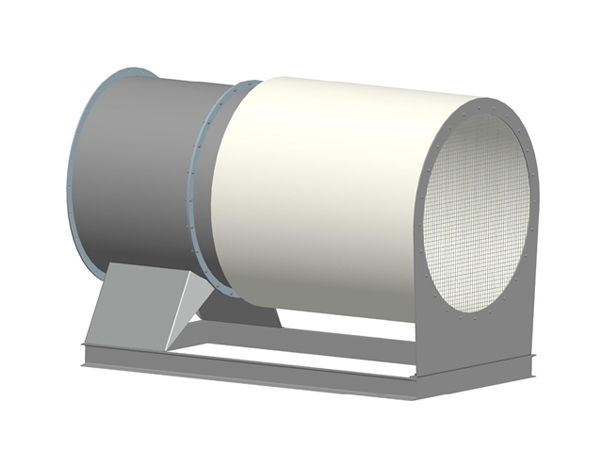

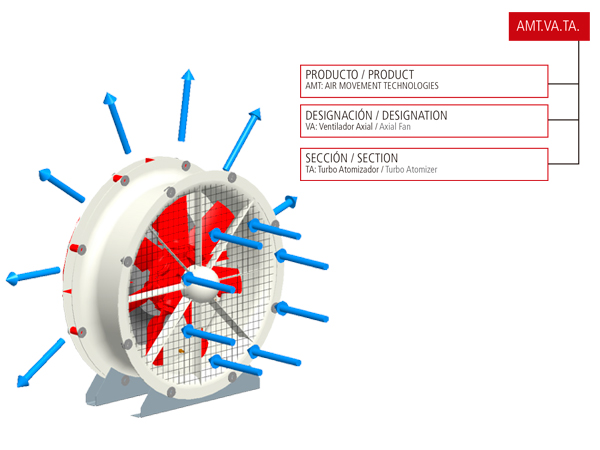

DESCRIPTION

Turbo Atomizers or Hydraulic Sprayers are a modified version of conventional Axial Fans, with the difference that these, by using a system Dripping into the air stream generated by the same fan, allow the user to disperse different types of sprayed fluid in different directions.

Our associates have invested a lot of time and technology to ensure that the Turbo Atomizer has unique and high quality features. The innumerable advances in this project

have made it possible to improve fundamental aspects such as low consumption, precision in the direction of the sprayed fluid and

better use of it.

The innovative design and the use of high quality light and resistant materials make these Turbo Atomizers have a robust and compact construction as well as being very quiet.

Our wide range of dimensions means that we can offer the customer a quality product that satisfies all your needs, as well as offering tailor-made products.

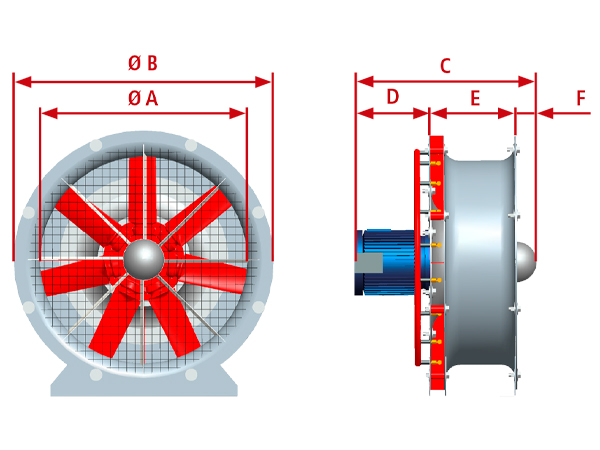

| Ø A (mm) | Ø B (mm) | C (mm) | D (mm) | E (mm) | F (mm) |

|---|---|---|---|---|---|

| 400 | 500 | 450 | 200 | 200 | 50 |

| 450 | 550 | 475 | 200 | 225 | 50 |

| 500 | 600 | 500 | 200 | 250 | 50 |

| 550 | 650 | 525 | 200 | 275 | 50 |

| 600 | 700 | 550 | 200 | 300 | 50 |

| 650 | 750 | 575 | 200 | 325 | 50 |

| 700 | 800 | 600 | 200 | 350 | 50 |

| 750 | 850 | 625 | 200 | 375 | 50 |

| 800 | 900 | 650 | 200 | 400 | 50 |

| 850 | 950 | 675 | 200 | 425 | 50 |

| 900 | 1000 | 700 | 200 | 450 | 50 |

| 950 | 1050 | 725 | 200 | 475 | 50 |

| 1000 | 1100 | 750 | 200 | 500 | 50 |

| 1050 | 1150 | 775 | 200 | 525 | 50 |

| 1100 | 1200 | 800 | 200 | 550 | 50 |

| 1150 | 1250 | 825 | 200 | 575 | 50 |

| 1200 | 1300 | 850 | 200 | 600 | 50 |

| 1250 | 1350 | 875 | 200 | 625 | 50 |

| 1300 | 1400 | 900 | 200 | 650 | 50 |

| 1350 | 1450 | 925 | 200 | 675 | 50 |

| 1400 | 1500 | 950 | 200 | 700 | 50 |

| 1450 | 1550 | 975 | 200 | 725 | 50 |

| 1500 | 1600 | 1000 | 200 | 750 | 50 |

| 1550 | 1650 | 1025 | 200 | 775 | 50 |

ACCESSORIES

REGULATION

RADIAL VALVES

OPPOSITE OR PARALLEL VALVE VALVES

BUTTERFLY VALVES

ELECTRIC AND PNEUMATIC ACTUATORS

FILTERS

FILTERS

SILENCERS

CIRCULAR AND RECTANGULAR SILENCERS

INSULATION

THERMAL-ACOUSTIC INSULATION

DUCTS

CIRCULAR AND RECTANGULAR REELS

DERIVATIONS

SECTION TRANSFORMERS

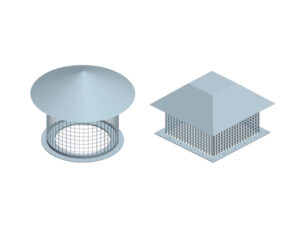

HATS

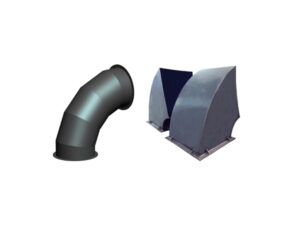

ELBOWS

CIRCULAR AND RECTANGULAR EXPANSION COMPENSATORS

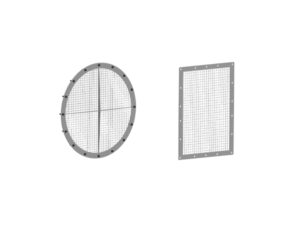

FLOW STRAIGHTENERS

SECURITY GRILLS

MATERIALS

SECTORS

Depending on the working conditions of the equipment, the appropriate materials are selected for each case, and the design is optimized for the most demanding cases.

- Carbon Steels

- Stainless steels

- High elastic limit steels

- Steels for high temperature

- Anti-wear materials and bimetals in critical areas of the rotor and casing

We are aimed at the following sectors:

- Power generation

- Paper

- Steel

- Petrochemical

- Cement

- Tunnels

- Oil and gas

- Metals and minerals

- Chemical

- Pharmacist

- Maritime

- Glass

- Agroindustry