DESCRIPTION

Tissue compensators, or tissue expansion joints, are flexible connectors designed to provide stress relief in conduction systems by absorbing movement.

They are used to solve four main situations:

– The expansion and contraction of the duct due to changes in temperature.

– Component isolation to minimize the effects of vibration and noise.

– The movement of components during process operations.

– Installation or disassembly of large components and assembly tolerances or adjustments.

Advantages of fabric compensators include:

– Large movements in short length.

– Ability to easily absorb simultaneous movements in more than one plane.

– Very low forces are needed to move the compensator.

– Corrosion resistant construction materials.

– Resistance to noise and vibration.

– Ease of installation and maintenance.

– Minimum replacement cost.

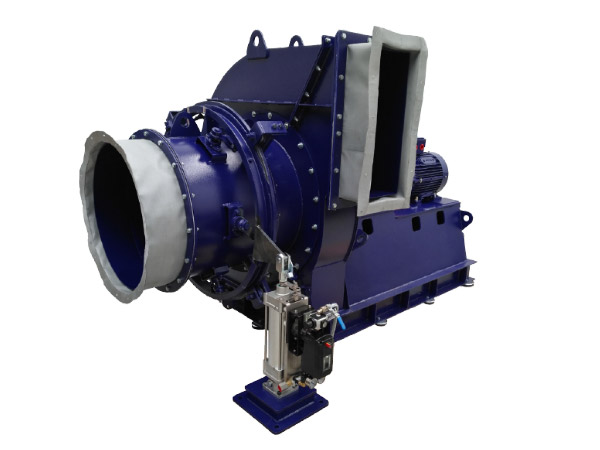

Depending on the sector and the working conditions, the type of construction and the compensator materials, we adapt to these conditions to provide the best service at a competitive price. Our associates normally use compensators in installations together with industrial centrifugal and axial fans, but they can also be installed at any point in the installation where it is needed.

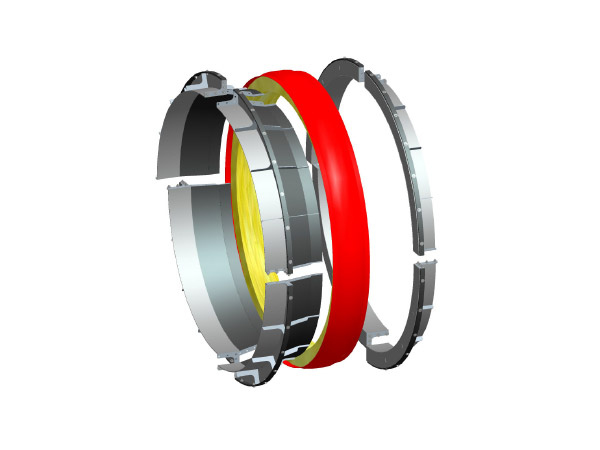

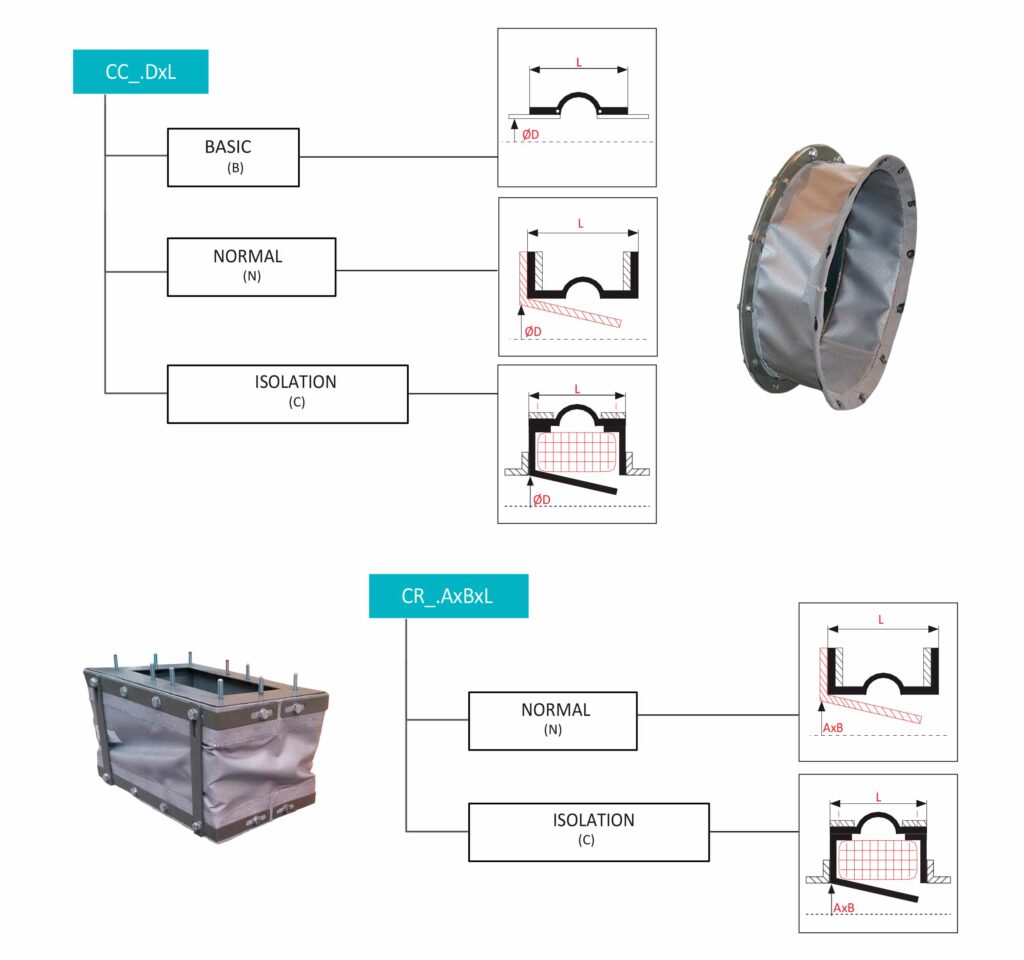

The effectiveness of the compensator depends on the design of the frames to which the flexible element is attached. It is possible to make many variants of frames, depending on the structure to which the compensator is attached. To respond to the different requirements of each application, our associates have developed many different designs and forms of construction.

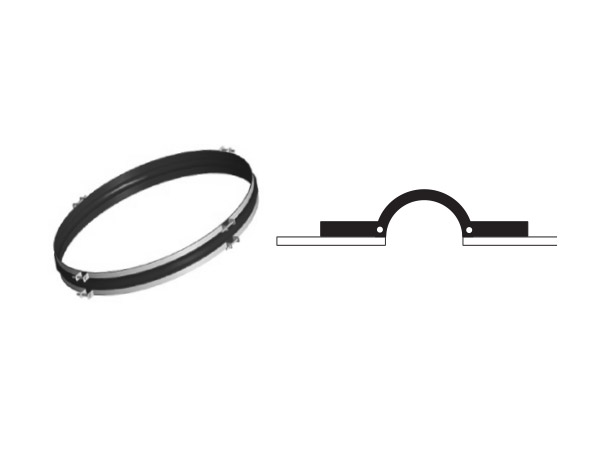

SINGLE BAND WITH CLAMP

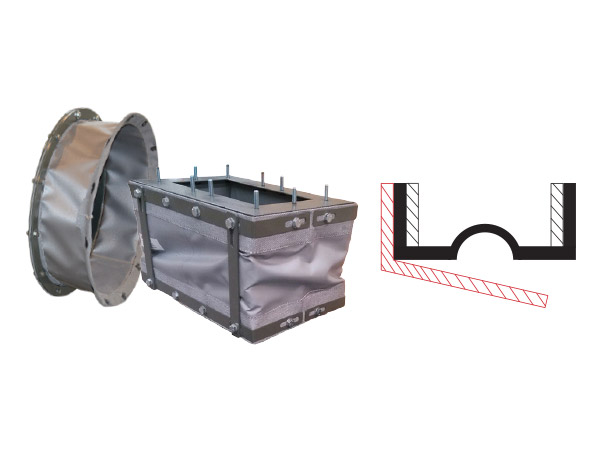

FLANGED COMPENSATOR

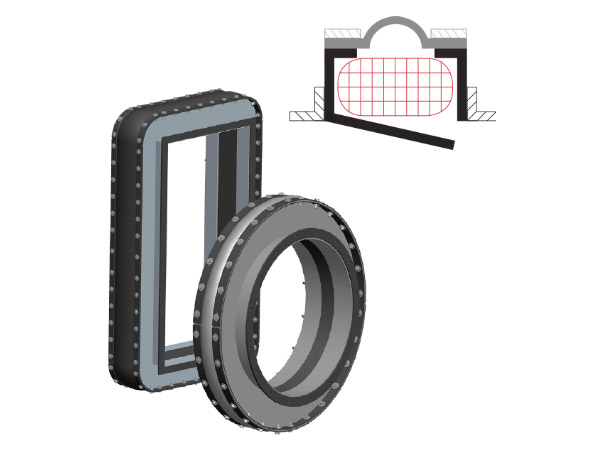

BAND TYPE COMPENSATOR

MANUFACTURING

SUPERFICIAL TREATMENTS

MOUNTING

MATERIALS

We manufacture with different materials depending on the operating conditions of the fluid. The parameters that influence the selection of the fabric material are: Pressure and temperature of the fluid that circulates inside the duct.

To determine the materials of the metal parts we would need the characteristics of the fluid and its composition. The materials we usually work with are: S275JR, AISI-304L, AISI-316L, 16Mo3, HARDOX-400 …

For fluids with abrasive particles we use anti-wear materials to make the compensator durable. We select the most suitable material for the operating conditions, or we manufacture under the indications or regulations of the customer’s installation.

DOCUMENTATION

INTERNAL DEFLECTORS

BOLSTERS

Insulating element that provides additional thermal protection to the compensator through the use of insulating materials. They improve the acoustic performance of the compensator, prevent solid particles from entering the compensator cavity, and provide support to the flexible element by minimizing the effects of vibrations.

SECTORS

Air Movement Technologies is aimed at the following sectors:

- Power generation

- Paper

- Steel

- Petrochemical

- Cement

- Tunnels

- Oil and gas

- Metals and minerals

- Chemical

- Pharmacist

- Maritime

- Glass

- Agroindustry