DESCRIPTION

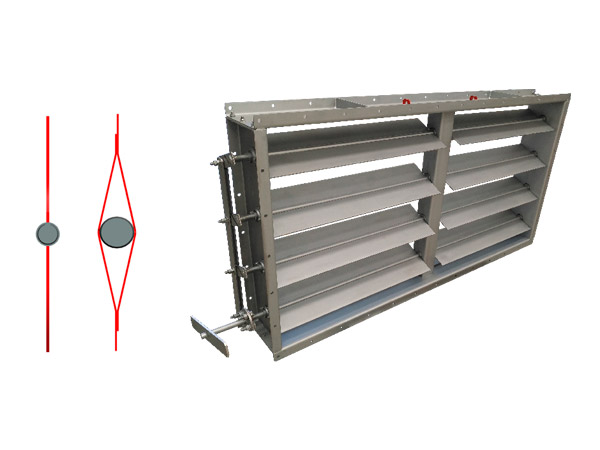

The louver dampers are, as the word well says, valves that allow or restrict the entry or exit of air, water, gas, etc. by means of a series of slats. These are used in oil fields and refineries, factories, ships, military bases, storage rooms for chemicals, paints or hazardous materials, underground facilities or nuclear power stations, and fulfill the function of control and / or isolation.

The louver valves are made up of: a frame and some louvers or leaves.

The most common materials with which the Valves are manufactured are aluminum and galvanized, stainless or mild steel and can have different shapes (square, rectangular or round) and openings / closures (manual, mechanical, electrical, pneumatic, hydraulic).

The valve slats can be of two types: aerodynamic or normal. They can also have, if needed, thermal insulation.

- Parallel blades: all their blades rotate in the same direction. It can offer up to 99% tightness. They are mainly used for isolation.

- Opposite slats: adjacent slats rotate in opposite directions. It allows you to gradually increase or decrease the flow, which allows you to have very good control characteristics. They are used for gas control.

- Double slats: designed to create insulation without any leakage, by means of a hermetic seal.

- Tandem: works in the same way as the double blade valve, with the difference that, instead of having the hermetic seal between sheets, it has it between the tandem vane liners wider.

We offer a totally customized design and manufacture of flap valves. We fully adapt to our client’s requirements, no matter how demanding.

We offer Valves made with top quality materials, so that the product can have a greater and better performance, and it obtains a maximum useful life.

When designing them, we study the different possibilities that exist, to offer the highest quality, as well as the creation of a Valve that has the fastest possible response, so that in case of emergencies, no type of problem arises.

We create Valves for both land and maritime areas, using different materials, seals, closures and drives. Always choosing those materials that are most suitable and will best fulfill their function.

DESCRIPTION

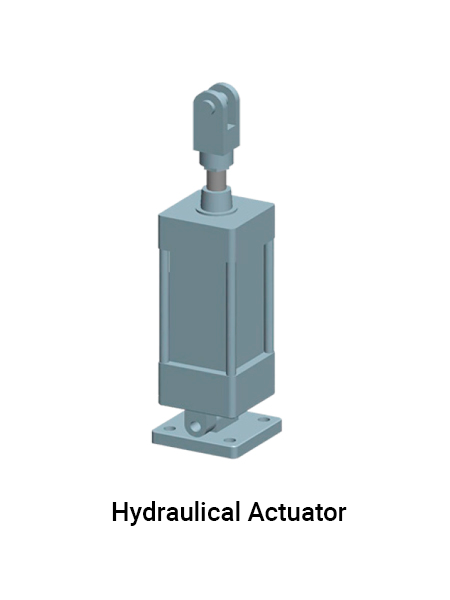

The Valves can be actuated by different actuators, which are:

- Electrical.

- Tire.

- Hydraulic.

- Mechanics.

DRIVES