C-102/C-202

You are here:

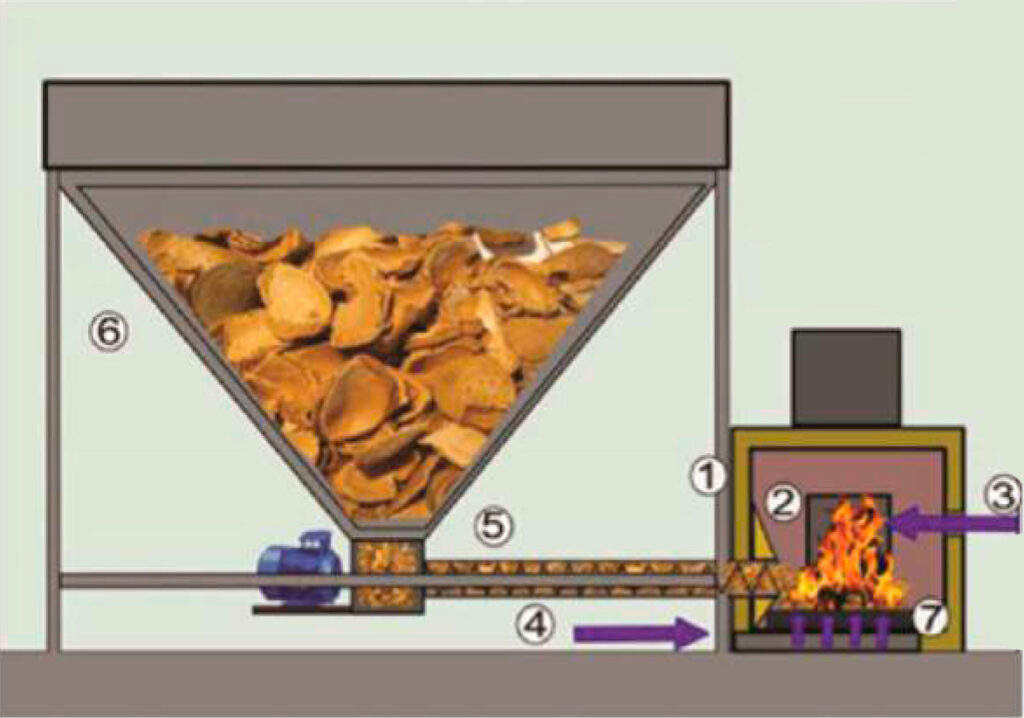

Hot air generator, specially designed for poultry farms that use all types of biomass fuel, Granulated, Dry and Clean.

| Technical Data | C-102 | C-202 |

|---|---|---|

| Rated thermal power (kW) | 140 | 250 |

| Maximum consumption (Kg/h) | 30 | 89 |

| Minimal consumption (Kg/h) | 11 | 11 |

| Nominal income (%) | 85 | 85 |

| Smoke temperature (oC) | 89 | 89 |

| Maximum power autonomy (h) | 36 | 25 |

| Minimum power autonomy (h) | 100 | 72 |

| Hopper capacity (L) | 1300 | 1300 |

| Heating capacity (m2) | 900 | 1600 |

| Smoke exit diameter (mm) | 150 | 150 |

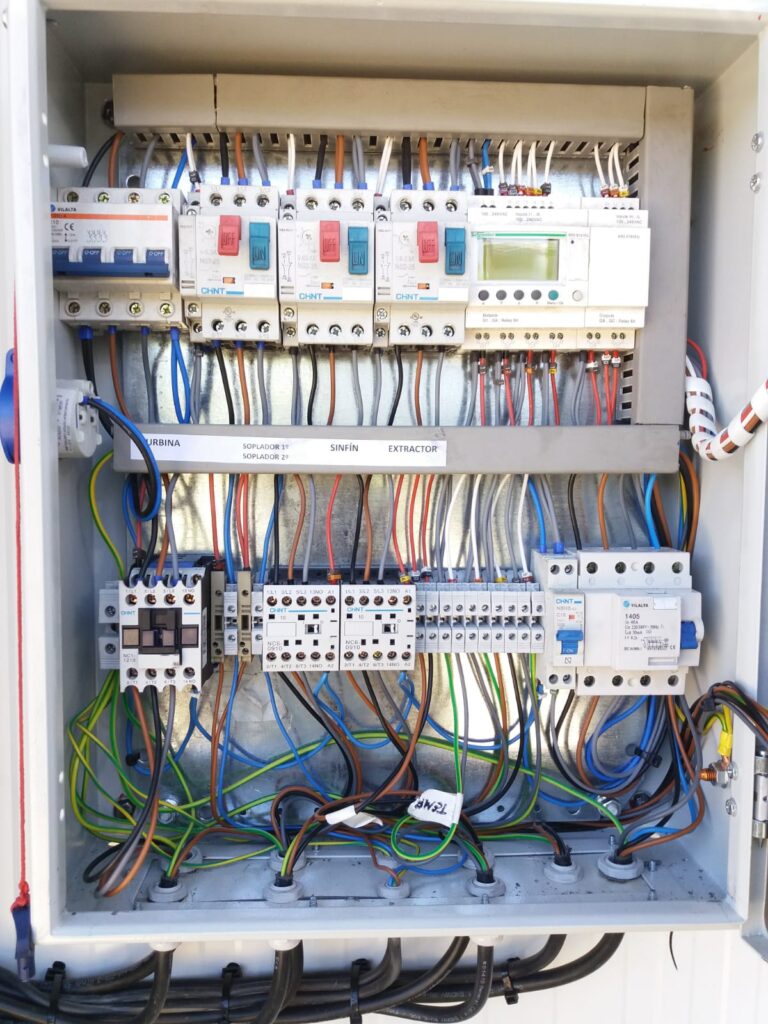

| Electrical power absorbed (kW) | 2.1 | 3.46 |

| Supply voltage (V) | 220/380 | 220/380 |

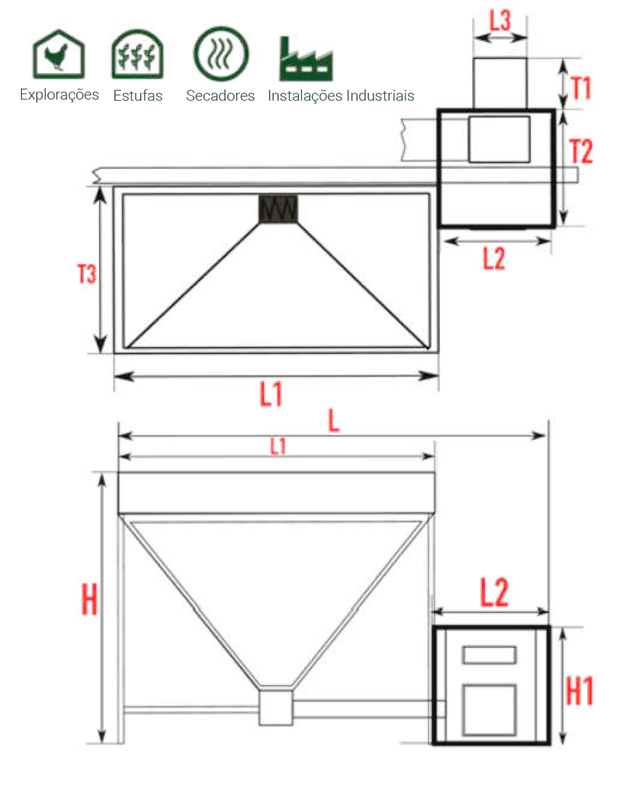

| C-102 | C-202 | |

|---|---|---|

| L | 2180 | 2500 |

| L1 | 1680 | 1580 |

| L2 | 700 | 910 |

| L3 | 300 | 300 |

| T1 | 350 | 350 |

| T2 | 1030 | 1200 |

| T3 | 1050 | 1050 |

| H | 2040 | 2040 |

| H1 | 630 | 860 |

Old building, open warehouse, tunnel type, chicken or turkey.

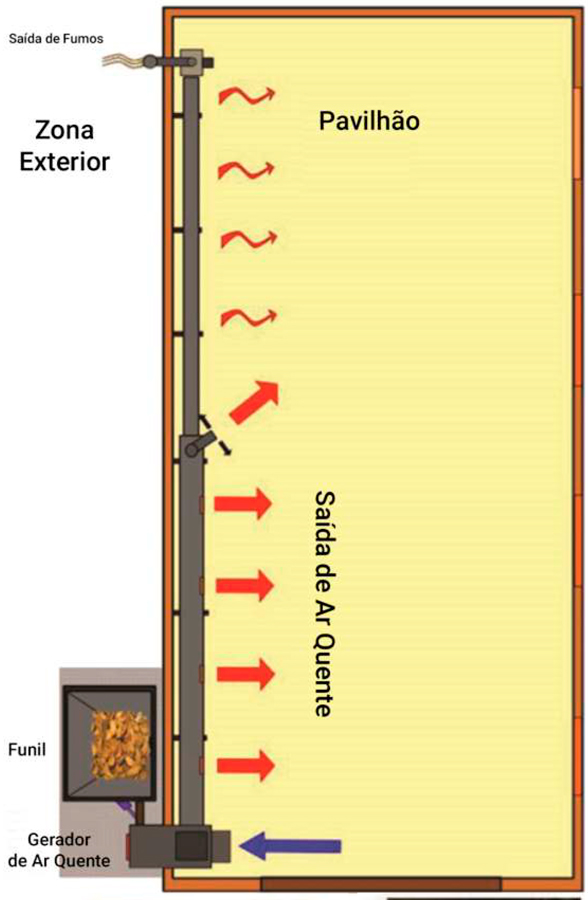

We have new models, C-140 and C-250 with the exchanger incorporated in the same body from the generator, managing to separate the equipment from the Pavilion and without the need for piping interior for greater comfort.

These equipments inject the hot air inside the building by means of a single connection by galvanized tube and derivations or elbows to direct the air.

In the same way, they collect the hot air from inside the building, also with galvanized pipe to take advantage of its temperature and obtain a higher yield. These generators are the same as those used in models C-102 and C-202, respectively.