The versatility of the hatches means that they can be used in a large number of different situations, such as ventilation, aeration, filling or inspection.

Both its structure, the materials with which it is composed or its various measures allow us to make the client adapt it to the need they want to cover.

DESCRIPTION

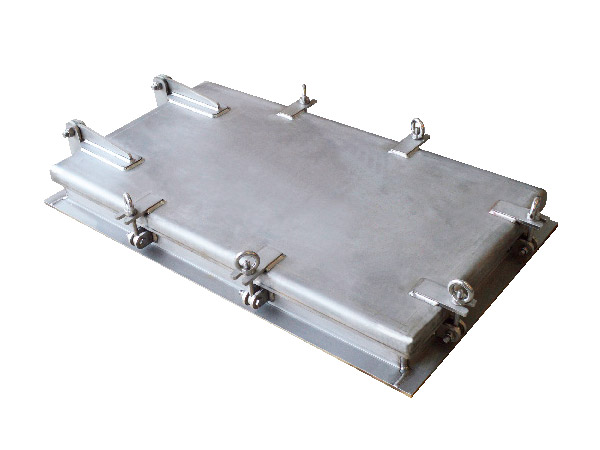

Hatchways or Hermetic Hatches are openings in the form of a hatch or access door found in a ship (located both on the deck and in height), drilling platform, container, renewable energy plant, wind farm, commercial building, areas with danger of flooding, etc. Its design can focus on different uses and, mainly, it must protect what is inside from the outside.

The most common materials with which the hatches are made are steel, aluminum or stainless steel. They can also have different finishes depending on what is required by the client, or even different shapes (round, square, oval), openings / locks (wheel, lever, lever clamp, gas springs, mechanical springs) or other options such as anti-skid blocking or application.

For marine or naval applications, a factor to take into account, regarding its design, could be if; This hatch will always remain open, except in an emergency, or if it will always remain closed, except when working in an adjacent compartment, when personnel are passing, or if it is closed before the trip and remains closed during the journey of this.

Within the boat hatches, we could differentiate between two types; the watertight hatches and the weathertight hatches, the difference between the two, is basically the area of the ship in which they are located. The former are located below the boat’s waterline (they protect the machinery, the shaft tunnel …), and the latter, above. The strength of hatches varies according to their qualities.

In addition to water protection, hatches can also be used for fire protection by applying a fire retardant coating.

In addition to those previously mentioned, we also have hermetic vapor elimination hatches, ideal for marine or offshore ventilation, in order to maintain acceptable working conditions for operators who are inside a compartment, or the option to combine different materials for the manufacture of the different parts that make up the hatch assembly.

When designing the hatch that our client has indicated, we take into consideration its use, destination, structure … In this way, and depending on the parameters, we can build it with the most suitable drive system. fast and simple that we can offer.

These are custom-made and fully customized designs, or created based on generic naval specifications.

Our associate has invested time and technology to ensure that our hatches have unique and high quality features. The important advances in these projects have allowed us to improve certain fundamental aspects of this product, such as a better compensation of the hinges, which makes our hatches more comfortable in manual use.

The use of resistant and high-quality materials makes our hatches have a robust and compact construction as well as being highly safe.

We have a wide range of dimensions and made-to-measure products, we adapt to our client with a product of the highest possible quality, which satisfies all their needs.