The mechanical characteristics of the equipment will also be governed based on design conditions given by the client, and its behavior will be studied to comply with these operating requirements.

To guarantee all of the above, the pertinent tests are carried out on the equipment, some of them routine standardized for each and every one of the fans, and others more specific on demand from the client.

Always certified and based on the standards, if any, that apply to each type of test or test.

In order to provide a more complete service and thus ensure clear warranty conditions for the client’s peace of mind, we provide technical assistance (SAT) for all the equipment supplied by us and even for those of other competing companies; We perform field circuit measurement, fan assembly and start-up supervision, including related tests and fluid dynamic and performance studies.

PRODUCT

The Industrial fan is a rotating machine, a piece of equipment with design characteristics that attend to some basic parameters for its definition and selection, being for us only one of several possibilities the most appropriate.

Based on some data on air flow, pressure (or load losses) in the circuit where the fan will be installed, and the temperature of the fluid itself, we can select a specific model that at a fixed or adjustable rotation speed by means of an electric motor , has a specific power consumption and performance (efficiency).

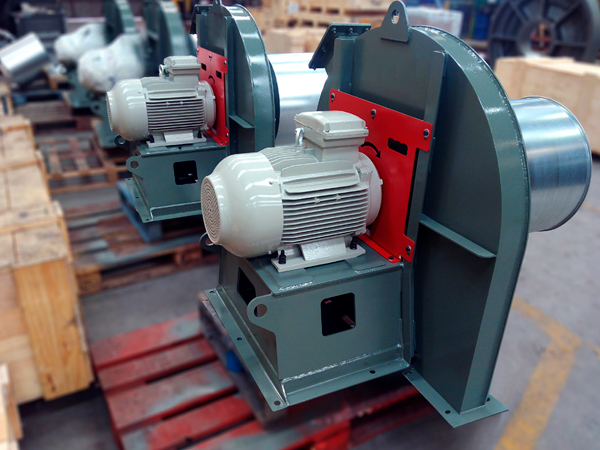

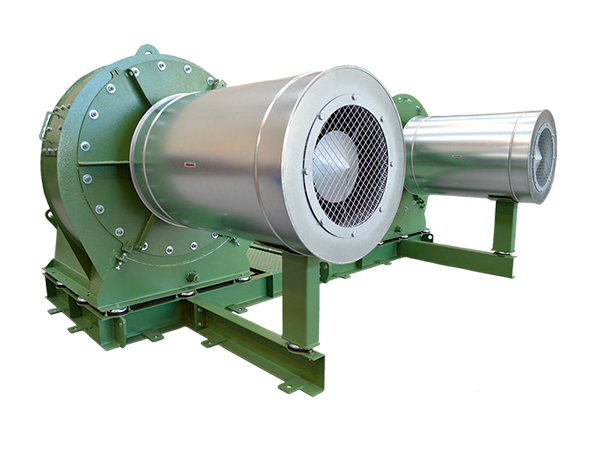

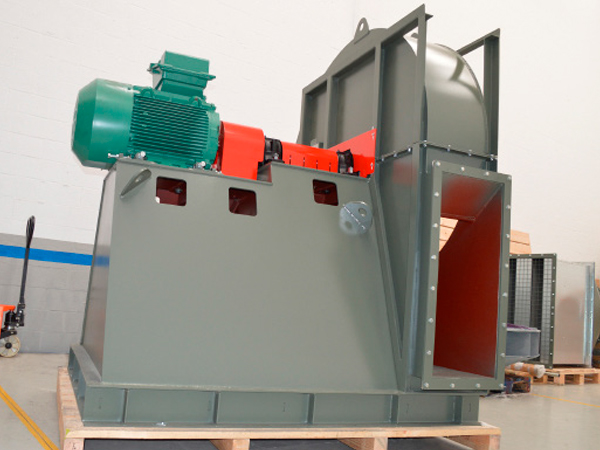

Our fans are custom designed and personalized, that is, starting from these initial operating conditions, the fan is chosen and later manufactured according to the needs or requirements of the client or the installation.

In conclusion, no two fans are the same, unless multiple units with the same characteristics are ordered.

CONFIGURATIONS

Depending on the design characteristics, one configuration or another would be selected, since sizes also have a direct impact on which is the most convenient. Our designs could move in a range of air flows between 1,000 m3 / h and 200,000 m3 / h, with pressures or head losses in the system of up to 15,000 Pa.

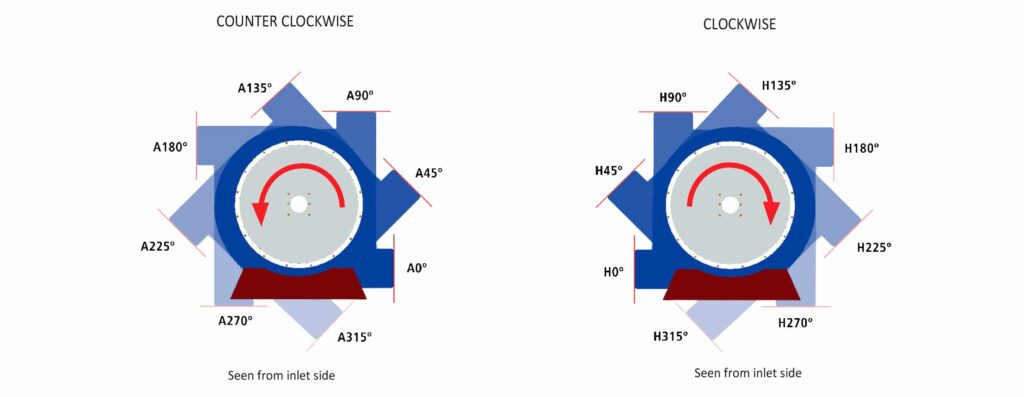

DIRECTIONS OF TURN / ROTATION

TYPE OF IMPELLER

Depending on the industrial sector in which we operate, or the type of application for which we are selecting the fan, the fluid conditions lead us to some models or others depending on the type of blade first, and the type of material later.

The fluid can be clean air, but it can also be dirty with particles, which would lead us to choose the most appropriate type of impeller and blade. The amount and type of particles would define the material, anti-wear in some cases when there is abrasion.

For cases of considerable humidity, or when we want to avoid corrosion, given the chemical composition of the air / gas we use stainless material for the parts in contact with the fluid.

Temperature often requires us to select one material or another, and in our case the possible range would go from -30ºC (below zero) to + 600ºC, by design.

ACCESSORIES

Within our range of accessories, we can cover practically all the needs of the installation in terms of elements of driving, control, safety, etc. it means.

This would roughly be our proposal on peripheral elements of the fan.

- Acoustic silencers for noise attenuation.

- Acoustic / thermal insulation systems using sound absorbing elements.

- Flexible and vibration isolation compensators.

- Flow regulating valves with manual or automatic actuators.

- Fluid control and stabilization systems.

- Maintenance facilities, structures, railings, etc.

- Piping systems, pipes, elbows, transition pieces, etc.

- Filtering elements for different efficiencies.

Within the possibilities of our equipment, special manufacturing also enters in accordance with requirements for explosive areas, classified with ATEX certification, or under technical specifications for the Petrochemical industry or refineries with API type regulations, these, based on rigorous design characteristics and operation.

Finally, it is worth highlighting the added value that we bring to our teams, with predictive maintenance systems at the forefront of Industry 4.0 and after-sales services. A technical assistance service (SAT) around the world and 2-year operational guarantees, extendable up to 5 years according to customer needs.